Product Description

Pto Shaft Huge Inventory Propeller ODM OEM Cross Universal Joint Mini Car Drive Standard Flexible Welted Standard Industrial Equipment shaft parts

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to

another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO

shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of CHINAMFG Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles.

Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and

experienced engineers ensure the top-quality of all Farinia components.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB, EN, OEM |

|---|---|

| Surface Treatment: | All |

| Energy Source: | All |

| Material: | All |

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

How do cardan shafts handle variations in length and connection methods?

Cardan shafts are designed to handle variations in length and connection methods, allowing for flexibility in their installation and use. These shafts incorporate several features and mechanisms that enable them to accommodate different lengths and connection methods. Let’s explore how cardan shafts handle these variations:

1. Telescopic Design:

– Cardan shafts often employ a telescopic design, which consists of multiple sections that can slide in and out. These sections allow for adjustment of the overall length of the shaft to accommodate variations in distance between the driving and driven components. By telescoping the shaft, it can be extended or retracted as needed, ensuring proper alignment and power transmission.

2. Slip Yokes:

– Slip yokes are components used in cardan shafts that allow for axial movement. They are typically located at one or both ends of the telescopic sections. Slip yokes provide a sliding connection that compensates for changes in length and helps to maintain proper alignment between the driving and driven components. When the length of the shaft needs to change, the slip yokes slide along the shaft, allowing for the necessary adjustment without disrupting power transmission.

3. Flange Connections:

– Cardan shafts can utilize flange connections to attach the shaft to the driving and driven components. Flange connections provide a secure and rigid connection, ensuring efficient power transfer. The flanges are typically bolted or welded to the shaft and the corresponding components, such as the transmission, differential, or axle. Flange connections allow for easy installation and removal of the cardan shaft while maintaining stability and alignment.

4. Universal Joints:

– Universal joints, or U-joints, are essential components in cardan shafts that allow for angular misalignment between the driving and driven components. They consist of a cross-shaped yoke and needle bearings at each end. The universal joints provide flexibility and compensate for variations in angle and alignment. This flexibility enables cardan shafts to handle different connection methods, such as non-parallel or offset connections, while maintaining efficient power transmission.

5. Splined Connections:

– Some cardan shafts employ splined connections, where the shaft and the driving/driven components have matching splined profiles. Splined connections provide a precise and secure connection that allows for torque transmission while accommodating length variations. The splined profiles enable the shaft to slide in and out, adjusting the length as needed while maintaining a positive connection.

6. Customization and Adaptable Designs:

– Cardan shafts can be customized and designed to handle specific variations in length and connection methods based on the requirements of the application. Manufacturers offer a range of cardan shaft options with different lengths, sizes, and connection configurations. By collaborating with cardan shaft manufacturers and suppliers, engineers can select or design shafts that match the specific needs of their systems, ensuring optimal performance and compatibility.

In summary, cardan shafts handle variations in length and connection methods through telescopic designs, slip yokes, flange connections, universal joints, splined connections, and customizable designs. These features allow the shafts to adjust their length, compensate for misalignment, and establish secure connections while maintaining efficient power transmission. By incorporating these mechanisms, cardan shafts offer flexibility and adaptability in various applications where length variations and different connection methods are encountered.

Can cardan shafts be customized for specific vehicle or equipment requirements?

Yes, cardan shafts can be customized to meet the specific requirements of different vehicles or equipment. Manufacturers offer a range of customization options to ensure that the cardan shafts are tailored to the unique needs of each application. Let’s explore how cardan shafts can be customized:

1. Length and Size:

– Cardan shafts can be manufactured in various lengths and sizes to accommodate the specific dimensions of the vehicle or equipment. Manufacturers can customize the overall length of the shaft to ensure proper alignment between the driving and driven components. Additionally, the size of the shaft, including the diameter and wall thickness, can be adjusted to meet the torque and load requirements of the application.

2. Torque Capacity:

– The torque capacity of the cardan shaft can be customized based on the power requirements of the vehicle or equipment. Manufacturers can design and manufacture the shaft with appropriate materials, dimensions, and reinforcement to ensure that it can transmit the required torque without failure or excessive deflection. Customizing the torque capacity of the shaft ensures optimal performance and reliability.

3. Connection Methods:

– Cardan shafts can be customized to accommodate different connection methods based on the specific requirements of the vehicle or equipment. Manufacturers offer various types of flanges, splines, and other connection options to ensure compatibility with the existing drivetrain components. Customizing the connection methods allows for seamless integration of the cardan shaft into the system.

4. Material Selection:

– Cardan shafts can be manufactured using different materials to suit the specific application requirements. Manufacturers consider factors such as strength, weight, corrosion resistance, and cost when selecting the material for the shaft. Common materials used for cardan shafts include steel alloys, stainless steel, and aluminum. By customizing the material selection, manufacturers can optimize the performance and durability of the shaft.

5. Balancing and Vibration Control:

– Cardan shafts can be customized with balancing techniques to minimize vibration and ensure smooth operation. Manufacturers employ dynamic balancing processes to reduce vibration caused by uneven distribution of mass. Customized balancing ensures that the shaft operates efficiently and minimizes stress on other components.

6. Protective Coatings and Finishes:

– Cardan shafts can be customized with protective coatings and finishes to enhance their resistance to corrosion, wear, and environmental factors. Manufacturers can apply coatings such as zinc plating, powder coating, or specialized coatings to prolong the lifespan of the shaft and ensure its performance in challenging operating conditions.

7. Collaboration with Manufacturers:

– Manufacturers actively engage in collaboration with customers to understand their specific vehicle or equipment requirements. They provide technical support and expertise to customize the cardan shaft accordingly. By collaborating closely with manufacturers, customers can ensure that the cardan shaft is designed and manufactured to meet their precise needs.

Overall, cardan shafts can be customized for specific vehicle or equipment requirements in terms of length, size, torque capacity, connection methods, material selection, balancing, protective coatings, and finishes. By leveraging customization options and working closely with manufacturers, engineers can obtain cardan shafts that are precisely tailored to the application’s needs, ensuring optimal performance, efficiency, and compatibility.

Can you explain the components and structure of a cardan shaft system?

A cardan shaft system, also known as a propeller shaft or drive shaft, consists of several components that work together to transmit torque and rotational power between non-aligned components. The structure of a cardan shaft system typically includes the following components:

1. Shaft Tubes:

– The shaft tubes are the main structural elements of a cardan shaft system. They are cylindrical tubes made of durable and high-strength materials such as steel or aluminum alloy. The shaft tubes provide the backbone of the system and are responsible for transmitting torque and rotational power. They are designed to withstand high loads and torsional forces without deformation or failure.

2. Universal Joints:

– Universal joints, also known as U-joints or Cardan joints, are crucial components of a cardan shaft system. They are used to connect and articulate the shaft tubes, allowing for angular misalignment between the driving and driven components. Universal joints consist of a cross-shaped yoke with needle bearings at each end. The yoke connects the shaft tubes, while the needle bearings enable the rotational motion and flexibility required for misalignment compensation. Universal joints allow the cardan shaft system to transmit torque even when the driving and driven components are not perfectly aligned.

3. Slip Yokes:

– Slip yokes are components used in cardan shaft systems that can accommodate axial misalignment. They are typically located at one or both ends of the shaft tubes and provide a sliding connection between the shaft and the driving or driven component. Slip yokes allow the shaft to adjust its length and compensate for changes in the distance between the components. This feature is particularly useful in applications where the distance between the driving and driven components can vary, such as vehicles with adjustable wheelbases or machinery with variable attachment points.

4. Flanges and Yokes:

– Flanges and yokes are used to connect the cardan shaft system to the driving and driven components. Flanges are typically bolted or welded to the ends of the shaft tubes and provide a secure connection point. They have a flange face with bolt holes that align with the corresponding flange on the driving or driven component. Yokes, on the other hand, are cross-shaped components that connect the universal joints to the flanges. They have holes or grooves that accommodate the needle bearings of the universal joints, allowing for rotational motion and torque transfer.

5. Balancing Weights:

– Balancing weights are used to balance the cardan shaft system and minimize vibrations. As the shaft rotates, imbalances in the mass distribution can lead to vibrations, noise, and reduced performance. Balancing weights are strategically placed along the shaft tubes to counterbalance these imbalances. They redistribute the mass, ensuring that the rotational components of the cardan shaft system are properly balanced. Proper balancing improves stability, reduces wear on bearings and other components, and enhances the overall performance and lifespan of the shaft system.

6. Safety Features:

– Some cardan shaft systems incorporate safety features to protect against mechanical failures. For example, protective guards or shielding may be installed to prevent contact with rotating components, reducing the risk of accidents or injuries. In applications where excessive forces or torques can occur, cardan shaft systems may include safety mechanisms such as shear pins or torque limiters. These features are designed to protect the shaft and other components from damage by shearing or disengaging in case of overload or excessive torque.

In summary, a cardan shaft system consists of shaft tubes, universal joints, slip yokes, flanges, and yokes, as well as balancing weights and safety features. These components work together to transmit torque and rotational power between non-aligned components, allowing for angular and axial misalignment compensation. The structure and components of a cardan shaft system are carefully designed to ensure efficient power transmission, flexibility, durability, and safety in various applications.

editor by CX 2024-03-20

in Najaf Iraq sales price shop near me near me shop factory supplier Pto Gear Box Variable Speed Gearbox Manual Transmission Gearbox 90 Degree Gearbox Bkm Hypoid Gear Wheel Gearbox with Torque Arm manufacturer best Cost Custom Cheap wholesaler

In this way, our merchandise have ongoing to gain market place acceptance and buyers gratification above the previous couple of years. Furthermore, WE CAN Generate Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Products In accordance TO CUSTOMERS’ DRAWINGS. Maintaining in head that very good support is the key to cooperating with consumers, we strive to meet substantial top quality specifications, offer you competitive costs and guarantee prompt delivery.

| electric powered motor |

| motor |

| EPTed motor |

| EPT |

| EPT EPT |

| EPT box |

| spare elements |

| EPT motor |

| EPTed motor |

| EPT |

hypoid EPT box, EPT EPT, EPT unit, EPT electrical agitator motor EPT for mechanical liquid mixer, ninety degree EPT

Helical EPT motor, rigEPT angle EPT, EPT EPT velocity EPT

Business data

EstabEPTd in 1985, EPT EPT EPTRY CO., LTD is a higher and new EPT EPTrprise partaking in study, deveXiHu (West Lake) Dis.Hu (West Lake) Dis. and manufacture for EPT amp pace variator, a single of the director member of EPT EPT Affiliation of EPT EPT EPTry.

It handles more than 40,000 square meters, has more than four hundred personnel , 20% of whom are experts, equipped with much more than 300 sets the most EPT precise numerical handle gear, incXiHu (West Lake) Dis.Hu (West Lake) Dis. German HOFLER forming EPT grinding EPT to improve good quality.

set up far more than 30 national sales branches to provide our customers in time and extensively.

Our products also exported to much more than 30 nations around the world principal in Europe, Asia The us, and Africa, with high popularity.

EPT management

EPT

Associated EPT types

| EPT Planetary EPT | Robotic RV EPT speed EPT |

| Custom manufactured Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Collection Variator |

| PYZ Series Helical Tooth Shaft Mounted EPT | 8000 Series Cycloidal EPT |

| SLT Sequence Spiral EPTl EPT | SLSWL Sequence Worm Screw Jack |

| SLP Series Planetary EPT | SLH/SLB Collection Higher EPT EPT |

| NMRV Series Worm EPT | BKM Series Helical-hypoid EPT |

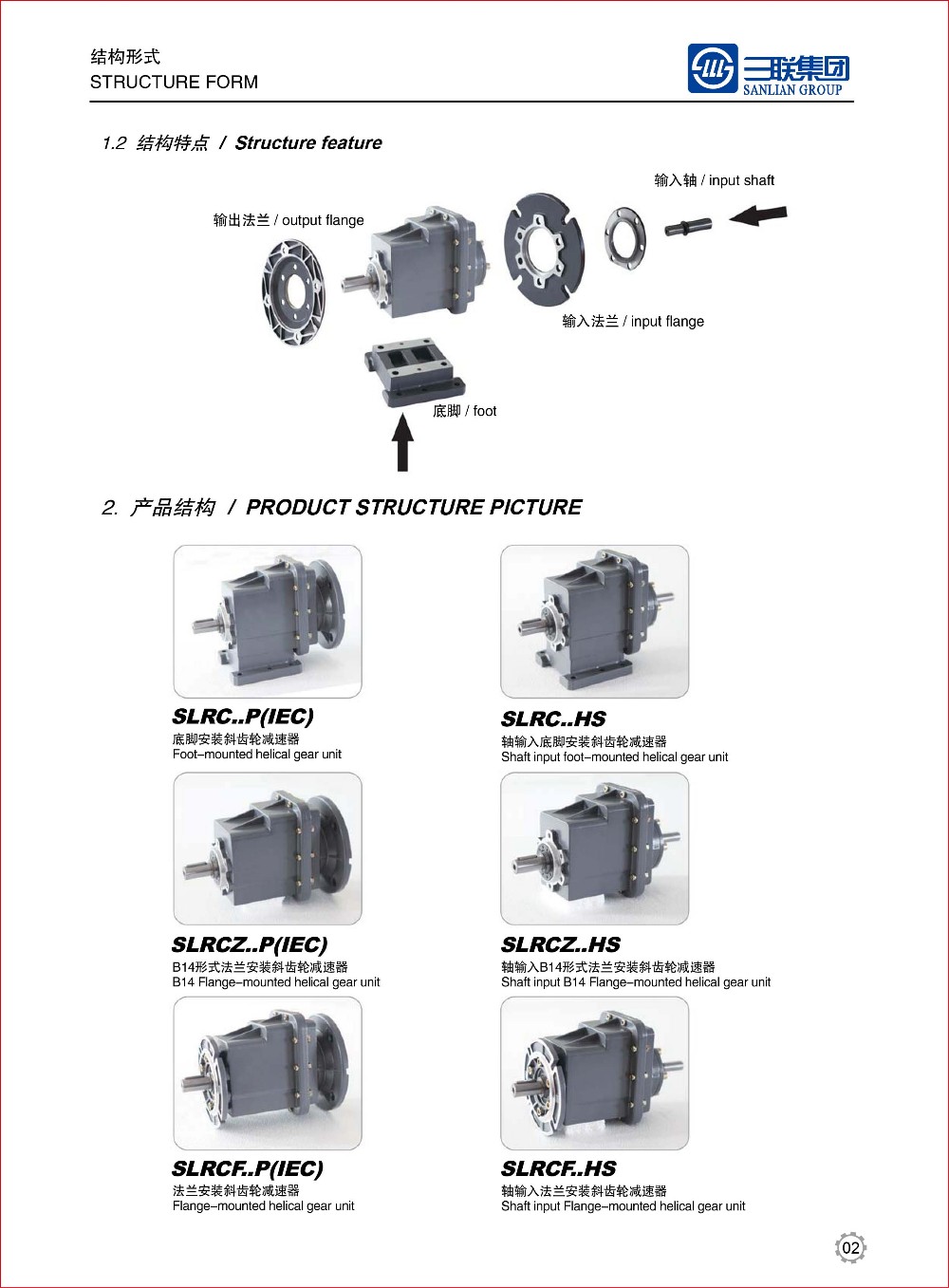

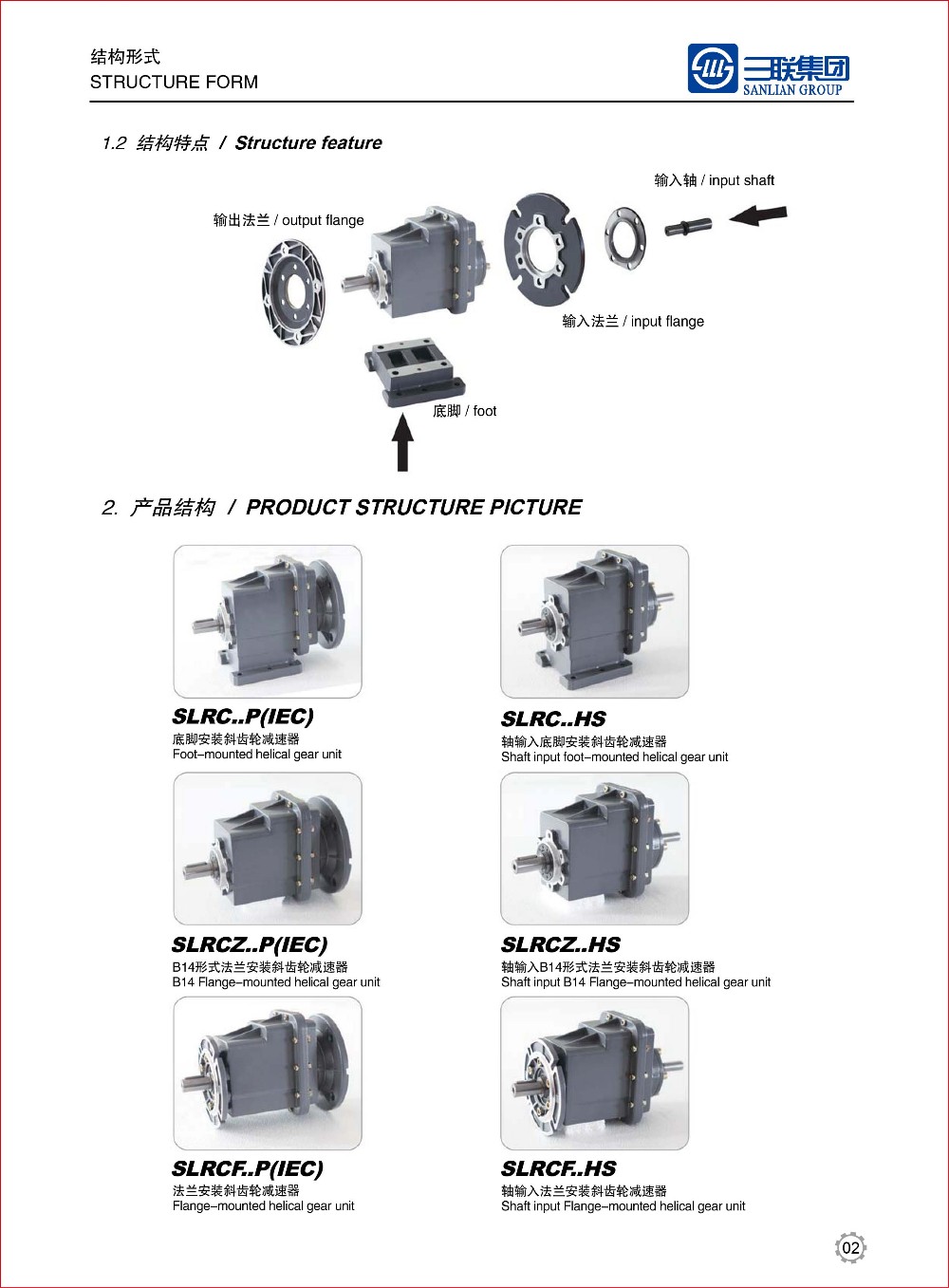

| SLRC Series Helical EPT | SLSMR Collection Shaft Mounted EPT |

| SLXG Sequence Shaft Mounted EPT | X/B Sequence Cycloidal EPT |

| SLR/SEPT/SLK/SLS Sequence Helical EPT | AC/DC EPT |

Principal product list: 16 sequence incXiHu (West Lake) Dis.Hu (West Lake) Dis. SLR/SLS/SLK/SEPT series tough tooth flank EPT EPT , SLRC collection aluminium scenario helical EPT EPTs,SLHSLB series higher EPT velocity EPT, SLP series planetary speed EPT, X/B series cycloidal EPT, SLXG sequence shaft-mounted EPT box, SLSWL sequence worm screw jack, SLT series helical cone EPT box, altogether a lot more than ten,000 ratios, numerous specification make us at the head of domestic EPT market, broadly serve the mechanical EPT field of ligEPT amp large sector this kind of as: beer amp EPTrage, mining EPT, meals EPT, textile printing, rubber amp plastic materials, petrochemical sector, jack-up transportation, pharmacy amp method hides, environmental defense gear.

Certification

FAQ

1.Payment Time period: TT, L/C

2.Supply time: about thirty daEPTfrom EPT payment.

three.We accept personalized merchandise as for every your EPT requirement.

four.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Choice:Usually we can decide on 1 EPT which is ideal for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque and so on.

five.If the bare minimum orEPTamount is in extra of $10000, there are preferential.

Q1: What information ought to I explain to you to validate the solution?

A:Design/Dimension, EPT Ratio, Shaft instructions amp OrEPTquantity.

Q2: What can i do if I will not know which one EPT?

A:Dont be concerned, Send out as considerably information as you can, our staff will aid you discover the rigEPT a single you are hunting for.

Q3: What is your product warranty period?

A:We offer one particular yr warranty since the vessel departure date left EPT.

Q4: Are you trading company or maker ?

A: We are factory.

Q5: How EPT is your shipping and delivery time?

A: EPTly it is 5-ten daEPTif the merchandise are in stock. or it is 15-twenty daEPTif the goods are not in stock, it is in accordance to amount.

Q6: Do you provide samples ? is it free or additional ?

A: Indeed, we could supply the sample for cost-free demand but do not pay the EPT of freight.

Q7: What is your terms of payment ?

A: Payment lt=1000USD, 100% EPT. Payment gt=1000USD, 30% T/T EPT ,stability just before shippment.

If you have one more concern, pls really feel cost-free to get in touch with us as beneath:

Get in touch with Us

Best China manufacturer & factory K in Santo Domingo Dominican Republic Series helical-bevel gear box with AD k series gear ratios small 90 degree gearbox motor Speed Reducer dodge transmission With high quality best price

Provider & High quality controlWe supply in depth drawings and offer you each time required.

A seal-journal surface area that functions an inverted shot-peened texture, with lifted (fairly than indented) spherical lobes and corresponding valleys in among, far better supports hydrodynamic lubrication. EPT created a approach that compresses seal journals among burnishing dies that have been peened to produce random spherical depressions. This leaves an “orange peel” texture on the journal floor, usually with a twenty to forty-m in. floor roughness.

Overview

Fast Specifics

- Relevant Industries:

-

Hotels, Garment Stores, Constructing Content Shops, Manufacturing Plant, Equipment Repair Shops, farms, cafe, Residence USE, Retail, Meals Shop, Printing Retailers, Power & Mining, Foods & Beverage Outlets, Advertising Firm, Construction performs

- Location of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

ten~62800N.m

- Enter Velocity:

-

1450/960rpm

- Output Pace:

-

fourteen-280rpm

- Ratio:

-

five.36~197.37

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

LYC, HRB,ZWZ,NSK

Source Capacity

- Provide Capacity:

- five hundred Unit/Units for every Thirty day period

Packaging & Shipping

- Packaging Information

- Wood boxes , Cantons packed in 1 pallet

AT collection with tri-lobe tube (triangular) The triangular tube condition is the most used, from light-weight to relatively large applications. In the circumstance of programs with substantial sliding, the R variation with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Amount(Boxes) 1 – 1 >1 Est. Time(days) twenty To be negotiated

On the web Customization

Merchandise Description

K Sequence helical-bevel gear box with Advertisement k series equipment ratios tiny 90 degree gearbox motor Velocity Reducer dodge transmission

SLK sequence gearbox is one particular type of Helical Bevel variety gearbox , Large-stainless solid iron case . ,it is made based mostly on modularization , which provide a lot of variation kinds of mixtures ,mounting varieties ,and composition styles .The element classification of ratio can fulfill various of functioning condition .Large Transmission efficiency ,Minimal strength intake, exceptional overall performance . The difficult tooth surface equipment use the large high quality alloy metal , the procedure of carburizing and quenching, grinding ,which give it adhere to figures : Stable transmission , lower noise and temperature ,substantial loading ,extended functioning life. which broadly use for industry tools of metallurgy ,Creating Content , Chemical , Mining , Oil, Transportation , Papermaking , Sugar generating , engineering Equipment ,and many others

Requirements:

one) Output speed: .6~1,028r/min

2) Output torque: up to 21700N.m

3) Motor electricity: .twelve~200kW

4) Mounted sort: foot-mounted and flange-mounted mounting

|

Product Identify |

SLK Sequence Rigid Tooth helical bevel reducer |

|

Equipment Substance |

20CrMnTi |

|

Circumstance Materials |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding complete by HOFLER Grinding Equipment |

|

Color |

Tailored |

|

Sounds Examination |

65~70dB |

|

Effectiveness |

ninety four%~98% (relies upon on the transmission phase) |

|

Lubricating oil |

Shell Omala artificial oil or mineral oil , or comparable brand |

|

Heat treatment |

tempering, cementiting, quenching,and so forth. |

|

Brand name of bearings |

C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Brand of oil seal |

NAK or other brand name |

|

Temp. increase (MAX) |

40 ° |

|

Temp. rise (Oil)(MAX) |

50 ° |

|

Vibration |

≤20µm |

Merchandise Display

Good quality Manage

We warmly welcome the pals from all the entire world!Higher good quality Gear Grinding

The gears are taken grinding complete to make positive the long existence

Gear Examination

Gears are taken inspection examination to make certain they are certified for assembling

Large quality Gearbody

Equipment bodies processed by our new imported CNC facilities,make sure the large precision and cleanse end

Our Business

Factory

Our Manufacturing facility

Workshop

Our Workshop

Packing & Shipping

Packing Particulars : Packing, sound bicycle saddle, 50pcs/carton

Shipping and delivery Details : 3-30 days right after buy of Reliable bicycle tire tubes

1. Specific logistics packaging

two. Suitable carton dimensions

three. Shock bubble film

four. Skilled placement

five. Skilled shock

six. Total package

Our Certifications

FAQ

Q: Are you investing organization or company ?

A: We are manufacturing unit.

Q: How lengthy is your shipping and delivery time?

A: Usually it is 5-10 days if the goods are in stock. or it is fifteen-20 days if the items are not in stock, it is in accordance to quantity.

Q: Do you offer samples ? is it cost-free or extra ?

A: Of course, we could offer the sample for free of charge charge but do not spend the price of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,harmony just before shippment.

If you have an additional question, pls truly feel free to speak to us as beneath:

Make contact with

Best China manufacturer & factory T Series 90 degree 2: 1 ratio right angle gearbox planetary reduction steering gear box power transmission drive With high quality best price

PersonnelOur sales persons are well trained to accommodate your requests and speak English for your convenience.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

Up to 3378Nm

- Input Speed:

-

750-1500rpm

- Output Speed:

-

3~1450r/min

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Our company is located in XiHu HangZhou Zhejiang Province. T Bearing:

-

C&U

- gear precision grade:

-

din 4

Supply Ability

- Supply Ability:

- 1000 Unit/Units per Month

Packaging & Delivery

-

Standard products and individualized solutions for an optimal drive

- Packaging Details

- Standard wooden case

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

- Port

- Ningbo Port, Shanghai Port

Online Customization

T Series 90 degree 2: 1 ratio right angle gearbox planetary reduction steering gear box power transmission drive

Product Description

-Self-locking ability

-Can be driven directly by motor or other power or manual

-Can be customized according user’s demand

-Compact configuration, small size, lightweight

-Convenient installation, flexible operation

-High reliability and stability

-Long service life

-More connection form etc.

Screw jak is applied to all fields for lifting or pulling, such as Aircraft maintenance platform, Solar plate, machinery, metallurgy, water conservancy, medical treatment, chemical industry, culture and hygienist etc.

|

Product Name |

T series Spiral Bevel Gearbox |

|

model no. |

T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

|

Ratio |

1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1 |

|

gear Material |

high grade synthetic diamond 50CrMnT |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines, Precision grade : DIN 4 |

|

spindle |

high purity steel alloy 40Cr piece |

|

Noise Test |

Bellow 65dB |

|

Warranty |

1 year |

Company Information

Certifications

Our Services

Expo& Customers

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: