Product Description

You can kindly find the specification details below:

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High-precision machinery products like the shaft, worm screw, bushing, couplings, joints……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, spline shafts, and stepped shafts that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ15(Customized) |

| Diameter Tolerance | f9(-0.016/-0.059) |

| Roundness | 0.05mm |

| Roughness | Ra0.8 |

| Straightness | 0.01mm |

| Hardness | HRC50-55 |

| Length | 257mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Customized |

|---|---|

| Condition: | New |

| Color: | Black |

| Certification: | CE, DIN, ISO |

| Type: | Universal Joint |

| Application Brand: | Nissan, Iveco, Toyota, Ford |

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of cardan shafts with different equipment?

Manufacturers take several measures to ensure the compatibility of cardan shafts with different equipment. These measures involve careful design, engineering, and manufacturing processes to meet the specific requirements of diverse applications. Let’s explore how manufacturers ensure compatibility:

1. Application Analysis:

– Manufacturers begin by analyzing the application requirements and specifications provided by customers. This analysis includes understanding factors such as torque, speed, misalignment, operating conditions, space limitations, and other specific needs. By evaluating these parameters, manufacturers can determine the appropriate design and configuration of the cardan shaft to ensure compatibility with the equipment.

2. Customization Options:

– Manufacturers offer customization options for cardan shafts to meet the unique requirements of different equipment. This includes providing various lengths, sizes, torque capacities, connection methods, and material options. Customers can work closely with manufacturers to select or design a cardan shaft that fits their specific equipment and ensures compatibility with the system’s power transmission needs.

3. Engineering Expertise:

– Manufacturers employ experienced engineers who specialize in cardan shaft design and engineering. These experts have in-depth knowledge of mechanical power transmission and understand the complexities involved in ensuring compatibility. They use their expertise to design cardan shafts that can handle the specific torque, speed, misalignment, and other parameters required by different equipment.

4. Computer-Aided Design (CAD) and Simulation:

– Manufacturers utilize advanced computer-aided design (CAD) software and simulation tools to model and simulate the behavior of cardan shafts in different equipment scenarios. These tools allow engineers to analyze the stress distribution, bearing performance, and other critical factors to ensure the shaft’s compatibility and performance. By simulating the cardan shaft’s behavior under various loading conditions, manufacturers can optimize its design and validate its compatibility.

5. Quality Control and Testing:

– Manufacturers have stringent quality control processes in place to ensure the reliability, durability, and compatibility of cardan shafts. They conduct thorough testing to verify the performance and functionality of the shafts in real-world conditions. This may involve testing for torque capacity, speed limits, vibration resistance, misalignment tolerance, and other relevant parameters. By subjecting the cardan shafts to rigorous testing, manufacturers can ensure their compatibility with different equipment and validate their ability to deliver reliable power transmission.

6. Adherence to Standards and Regulations:

– Manufacturers follow industry standards and regulations when designing and manufacturing cardan shafts. Compliance with these standards ensures that the shafts meet the necessary safety, performance, and compatibility requirements. Examples of such standards include ISO 9001 for quality management and ISO 14001 for environmental management. By adhering to these standards, manufacturers demonstrate their commitment to producing compatible and high-quality cardan shafts.

7. Collaboration with Customers:

– Manufacturers actively collaborate with customers to understand their equipment and system requirements. They engage in discussions, provide technical support, and offer guidance to ensure the compatibility of the cardan shafts. By fostering a collaborative relationship, manufacturers can address specific challenges and tailor the design and specifications of the shaft to meet the unique requirements of different equipment.

In summary, manufacturers ensure the compatibility of cardan shafts with different equipment through application analysis, customization options, engineering expertise, CAD and simulation tools, quality control and testing, adherence to standards, and collaboration with customers. These measures allow manufacturers to design and produce cardan shafts that meet the specific torque, speed, misalignment, and other requirements of various equipment, ensuring optimal compatibility and efficient power transmission.

Can cardan shafts be customized for specific vehicle or equipment requirements?

Yes, cardan shafts can be customized to meet the specific requirements of different vehicles or equipment. Manufacturers offer a range of customization options to ensure that the cardan shafts are tailored to the unique needs of each application. Let’s explore how cardan shafts can be customized:

1. Length and Size:

– Cardan shafts can be manufactured in various lengths and sizes to accommodate the specific dimensions of the vehicle or equipment. Manufacturers can customize the overall length of the shaft to ensure proper alignment between the driving and driven components. Additionally, the size of the shaft, including the diameter and wall thickness, can be adjusted to meet the torque and load requirements of the application.

2. Torque Capacity:

– The torque capacity of the cardan shaft can be customized based on the power requirements of the vehicle or equipment. Manufacturers can design and manufacture the shaft with appropriate materials, dimensions, and reinforcement to ensure that it can transmit the required torque without failure or excessive deflection. Customizing the torque capacity of the shaft ensures optimal performance and reliability.

3. Connection Methods:

– Cardan shafts can be customized to accommodate different connection methods based on the specific requirements of the vehicle or equipment. Manufacturers offer various types of flanges, splines, and other connection options to ensure compatibility with the existing drivetrain components. Customizing the connection methods allows for seamless integration of the cardan shaft into the system.

4. Material Selection:

– Cardan shafts can be manufactured using different materials to suit the specific application requirements. Manufacturers consider factors such as strength, weight, corrosion resistance, and cost when selecting the material for the shaft. Common materials used for cardan shafts include steel alloys, stainless steel, and aluminum. By customizing the material selection, manufacturers can optimize the performance and durability of the shaft.

5. Balancing and Vibration Control:

– Cardan shafts can be customized with balancing techniques to minimize vibration and ensure smooth operation. Manufacturers employ dynamic balancing processes to reduce vibration caused by uneven distribution of mass. Customized balancing ensures that the shaft operates efficiently and minimizes stress on other components.

6. Protective Coatings and Finishes:

– Cardan shafts can be customized with protective coatings and finishes to enhance their resistance to corrosion, wear, and environmental factors. Manufacturers can apply coatings such as zinc plating, powder coating, or specialized coatings to prolong the lifespan of the shaft and ensure its performance in challenging operating conditions.

7. Collaboration with Manufacturers:

– Manufacturers actively engage in collaboration with customers to understand their specific vehicle or equipment requirements. They provide technical support and expertise to customize the cardan shaft accordingly. By collaborating closely with manufacturers, customers can ensure that the cardan shaft is designed and manufactured to meet their precise needs.

Overall, cardan shafts can be customized for specific vehicle or equipment requirements in terms of length, size, torque capacity, connection methods, material selection, balancing, protective coatings, and finishes. By leveraging customization options and working closely with manufacturers, engineers can obtain cardan shafts that are precisely tailored to the application’s needs, ensuring optimal performance, efficiency, and compatibility.

Can you explain the components and structure of a cardan shaft system?

A cardan shaft system, also known as a propeller shaft or drive shaft, consists of several components that work together to transmit torque and rotational power between non-aligned components. The structure of a cardan shaft system typically includes the following components:

1. Shaft Tubes:

– The shaft tubes are the main structural elements of a cardan shaft system. They are cylindrical tubes made of durable and high-strength materials such as steel or aluminum alloy. The shaft tubes provide the backbone of the system and are responsible for transmitting torque and rotational power. They are designed to withstand high loads and torsional forces without deformation or failure.

2. Universal Joints:

– Universal joints, also known as U-joints or Cardan joints, are crucial components of a cardan shaft system. They are used to connect and articulate the shaft tubes, allowing for angular misalignment between the driving and driven components. Universal joints consist of a cross-shaped yoke with needle bearings at each end. The yoke connects the shaft tubes, while the needle bearings enable the rotational motion and flexibility required for misalignment compensation. Universal joints allow the cardan shaft system to transmit torque even when the driving and driven components are not perfectly aligned.

3. Slip Yokes:

– Slip yokes are components used in cardan shaft systems that can accommodate axial misalignment. They are typically located at one or both ends of the shaft tubes and provide a sliding connection between the shaft and the driving or driven component. Slip yokes allow the shaft to adjust its length and compensate for changes in the distance between the components. This feature is particularly useful in applications where the distance between the driving and driven components can vary, such as vehicles with adjustable wheelbases or machinery with variable attachment points.

4. Flanges and Yokes:

– Flanges and yokes are used to connect the cardan shaft system to the driving and driven components. Flanges are typically bolted or welded to the ends of the shaft tubes and provide a secure connection point. They have a flange face with bolt holes that align with the corresponding flange on the driving or driven component. Yokes, on the other hand, are cross-shaped components that connect the universal joints to the flanges. They have holes or grooves that accommodate the needle bearings of the universal joints, allowing for rotational motion and torque transfer.

5. Balancing Weights:

– Balancing weights are used to balance the cardan shaft system and minimize vibrations. As the shaft rotates, imbalances in the mass distribution can lead to vibrations, noise, and reduced performance. Balancing weights are strategically placed along the shaft tubes to counterbalance these imbalances. They redistribute the mass, ensuring that the rotational components of the cardan shaft system are properly balanced. Proper balancing improves stability, reduces wear on bearings and other components, and enhances the overall performance and lifespan of the shaft system.

6. Safety Features:

– Some cardan shaft systems incorporate safety features to protect against mechanical failures. For example, protective guards or shielding may be installed to prevent contact with rotating components, reducing the risk of accidents or injuries. In applications where excessive forces or torques can occur, cardan shaft systems may include safety mechanisms such as shear pins or torque limiters. These features are designed to protect the shaft and other components from damage by shearing or disengaging in case of overload or excessive torque.

In summary, a cardan shaft system consists of shaft tubes, universal joints, slip yokes, flanges, and yokes, as well as balancing weights and safety features. These components work together to transmit torque and rotational power between non-aligned components, allowing for angular and axial misalignment compensation. The structure and components of a cardan shaft system are carefully designed to ensure efficient power transmission, flexibility, durability, and safety in various applications.

editor by CX 2024-02-25

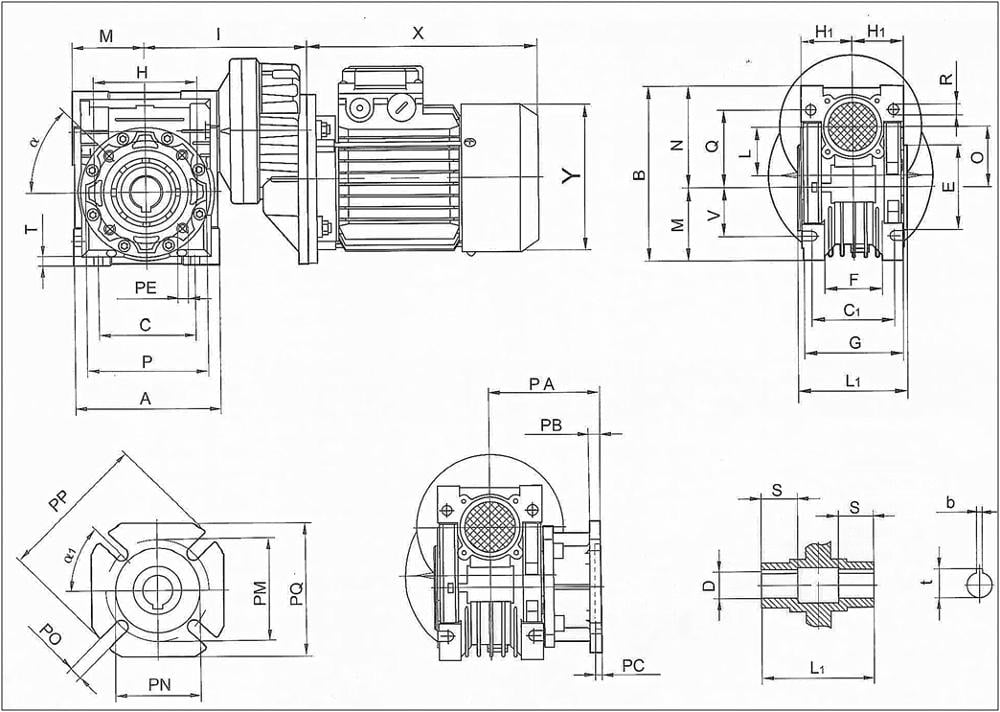

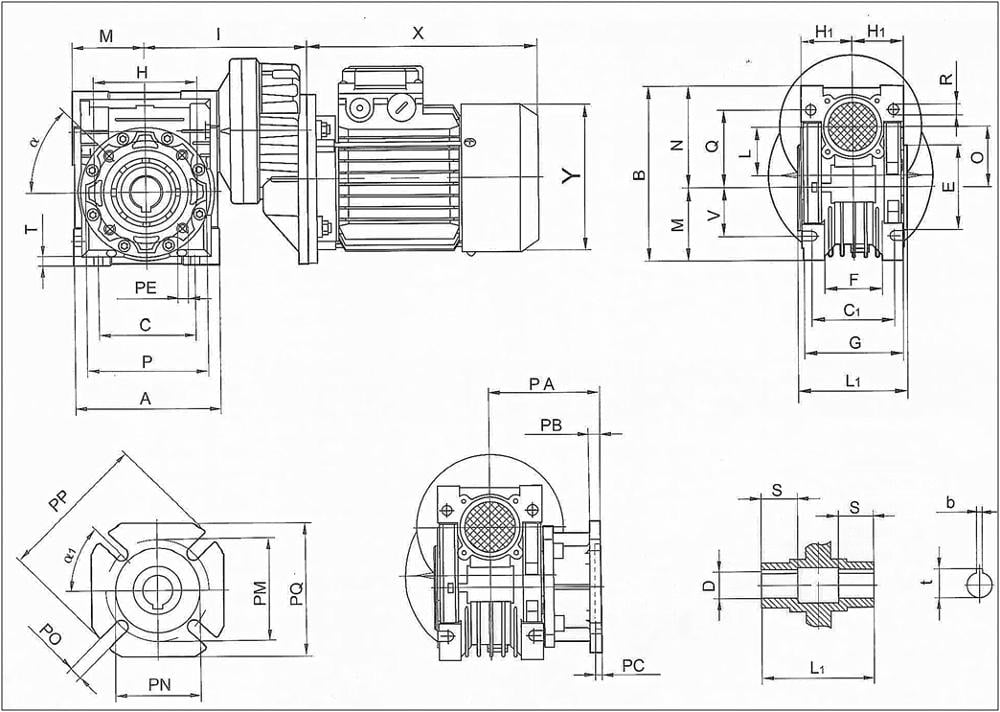

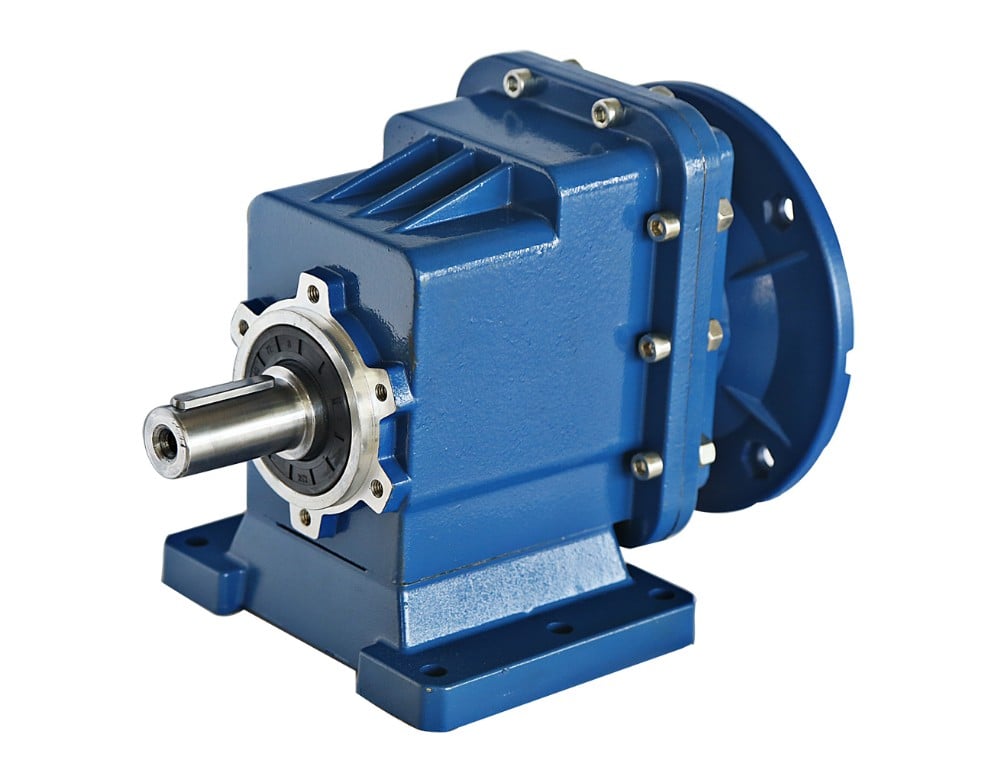

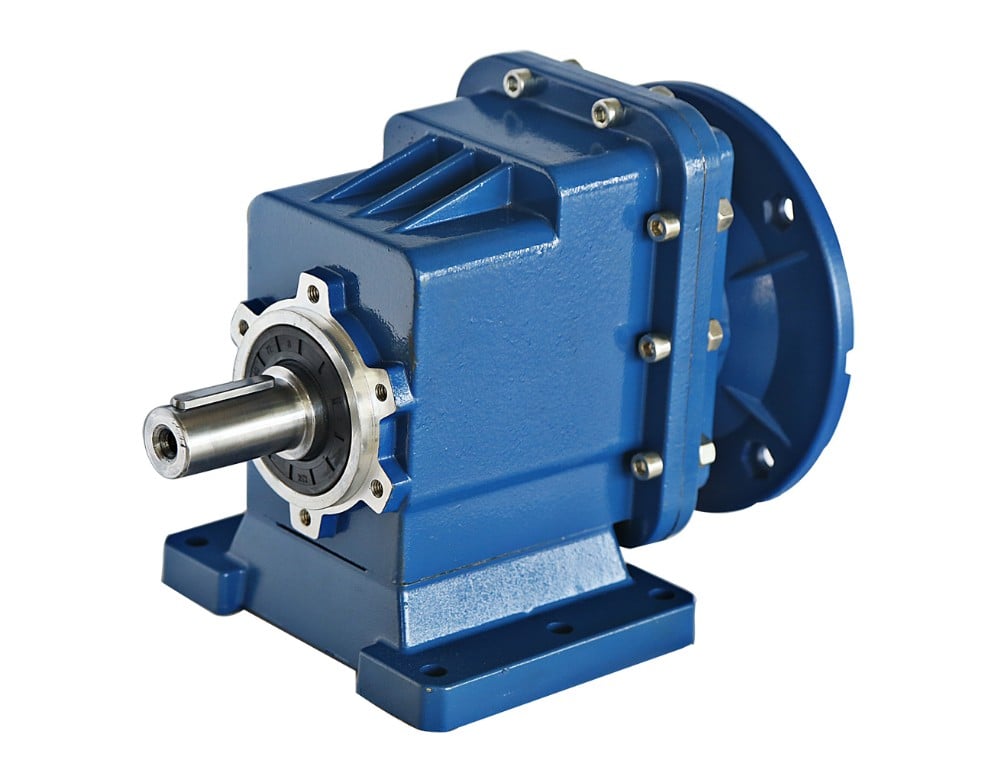

China Good quality 120 Cheap Price Can Be Custom Small Worm Gear Shaft Gearbox Motor Speed Reducer with Hot selling

Products Display Specification ModelSeriesReduction ratioRated output torque (Nm)Output maximum torque (Nm)Rated input speed (rpm)120I32304603000423046 0571 0460623046 0571 937 0571 937571032571160320 Enter the maximum speed (rpm)Allowable radial load (N)Allowable Axial Load (N)Maximum radial load (N)Maximum axial load (N)Backlash (arcmin)Moment of inertia≤Φ1460004200560 0571 07800≤55.3420056004.1420056003.6420056003.3420056003.2420056003.14200560571056003 Related Product Company Profile Certifications Why Choose Us Packing And Shipping FAQ Q1: Are you a trading company or manufacturer?A1: We are an experienced manufacturer. Q2: Can I have my own customized product?A2: Yes.OEM& WeiYou Hd700-7 Hd1250-7 Hd1430 Reduction Gearbox Part 1st 2nd 3rd Travel Planetary Carrier Ass’Y Sun Gear Shaft For CZPT ODM are available,including design, logo,package etc. Q3: What’ Wholesale Golf Shaft Adapter Sleeve .335 Tip CZPT made Driver Fairway RH Compatible with M1 M2 M3 M4 M5 M6 SIM SIM2 R15 Drive s the MOQ?A3: For inventory,the MOQ is 1set. Q4: What’s the delivery time?A4: Within 10 days for ready stock order.OEM&ODM order.The exact time depends on actual situation.

Worm Shafts and Gearboxes

If you have a gearbox, you may be wondering what the best Worm Shaft is for your application. There are several things to consider, including the Concave shape, Number of threads, and Lubrication. This article will explain each factor and help you choose the right Worm Shaft for your gearbox. There are many options available on the market, so don’t hesitate to shop around. If you are new to the world of gearboxes, read on to learn more about this popular type of gearbox.

Concave shape

The geometry of a worm gear varies considerably depending on its manufacturer and its intended use. Early worms had a basic profile that resembled a screw thread and could be chased on a lathe. Later, tools with a straight sided g-angle were developed to produce threads that were parallel to the worm’s axis. Grinding was also developed to improve the finish of worm threads and minimize distortions that occur with hardening.

To select a worm with the proper geometry, the diameter of the worm gear must be in the same unit as the worm’s shaft. Once the basic profile of the worm gear is determined, the worm gear teeth can be specified. The calculation also involves an angle for the worm shaft to prevent it from overheating. The angle of the worm shaft should be as close to the vertical axis as possible.

Double-enveloping worm gears, on the other hand, do not have a throat around the worm. They are helical gears with a straight worm shaft. Since the teeth of the worm are in contact with each other, they produce significant friction. Unlike double-enveloping worm gears, non-throated worm gears are more compact and can handle smaller loads. They are also easy to manufacture.

The worm gears of different manufacturers offer many advantages. For instance, worm gears are one of the most efficient ways to increase torque, while lower-quality materials like bronze are difficult to lubricate. Worm gears also have a low failure rate because they allow for considerable leeway in the design process. Despite the differences between the two standards, the overall performance of a worm gear system is the same.

The cone-shaped worm is another type. This is a technological scheme that combines a straight worm shaft with a concave arc. The concave arc is also a useful utility model. Worms with this shape have more than three contacts at the same time, which means they can reduce a large diameter without excessive wear. It is also a relatively low-cost model.

Thread pattern

A good worm gear requires a perfect thread pattern. There are a few key parameters that determine how good a thread pattern is. Firstly, the threading pattern must be ACME-threaded. If this is not possible, the thread must be made with straight sides. Then, the linear pitch of the “worm” must be the same as the circular pitch of the corresponding worm wheel. In simple terms, this means the pitch of the “worm” is the same as the circular pitch of the worm wheel. A quick-change gearbox is usually used with this type of worm gear. Alternatively, lead-screw change gears are used instead of a quick-change gear box. The pitch of a worm gear equals the helix angle of a screw.

A worm gear’s axial pitch must match the circular pitch of a gear with a higher axial pitch. The circular pitch is the distance between the points of teeth on the worm, while the axial pitch is the distance between the worm’s teeth. Another factor is the worm’s lead angle. The angle between the pitch cylinder and worm shaft is called its lead angle, and the higher the lead angle, the greater the efficiency of a gear.

Worm gear tooth geometry varies depending on the manufacturer and intended use. In early worms, threading resembled the thread on a screw, and was easily chased using a lathe. Later, grinding improved worm thread finishes and minimized distortions from hardening. As a result, today, most worm gears have a thread pattern corresponding to their size. When selecting a worm gear, make sure to check for the number of threads before purchasing it.

A worm gear’s threading is crucial in its operation. Worm teeth are typically cylindrical, and are arranged in a pattern similar to screw or nut threads. Worm teeth are often formed on an axis of perpendicular compared to their parallel counterparts. Because of this, they have greater torque than their spur gear counterparts. Moreover, the gearing has a low output speed and high torque.

Number of threads

Different types of worm gears use different numbers of threads on their planetary gears. A single threaded worm gear should not be used with a double-threaded worm. A single-threaded worm gear should be used with a single-threaded worm. Single-threaded worms are more effective for speed reduction than double-threaded ones.

The number of threads on a worm’s shaft is a ratio that compares the pitch diameter and number of teeth. In general, worms have 1,2,4 threads, but some have three, five, or six. Counting thread starts can help you determine the number of threads on a worm. A single-threaded worm has fewer threads than a multiple-threaded worm, but a multi-threaded worm will have more threads than a mono-threaded planetary gear.

To measure the number of threads on a worm shaft, a small fixture with two ground faces is used. The worm must be removed from its housing so that the finished thread area can be inspected. After identifying the number of threads, simple measurements of the worm’s outside diameter and thread depth are taken. Once the worm has been accounted for, a cast of the tooth space is made using epoxy material. The casting is moulded between the two tooth flanks. The V-block fixture rests against the outside diameter of the worm.

The circular pitch of a worm and its axial pitch must match the circular pitch of a larger gear. The axial pitch of a worm is the distance between the points of the teeth on a worm’s pitch diameter. The lead of a thread is the distance a thread travels in one revolution. The lead angle is the tangent to the helix of a thread on a cylinder.

The worm gear’s speed transmission ratio is based on the number of threads. A worm gear with a high ratio can be easily reduced in one step by using a set of worm gears. However, a multi-thread worm will have more than two threads. The worm gear is also more efficient than single-threaded gears. And a worm gear with a high ratio will allow the motor to be used in a variety of applications.

Lubrication

The lubrication of a worm gear is particularly challenging, due to its friction and high sliding contact force. Fortunately, there are several options for lubricants, such as compounded oils. Compounded oils are mineral-based lubricants formulated with 10 percent or more fatty acid, rust and oxidation inhibitors, and other additives. This combination results in improved lubricity, reduced friction, and lower sliding wear.

When choosing a lubricant for a worm shaft, make sure the product’s viscosity is right for the type of gearing used. A low viscosity will make the gearbox difficult to actuate and rotate. Worm gears also undergo a greater sliding motion than rolling motion, so grease must be able to migrate evenly throughout the gearbox. Repeated sliding motions will push the grease away from the contact zone.

Another consideration is the backlash of the gears. Worm gears have high gear ratios, sometimes 300:1. This is important for power applications, but is at the same time inefficient. Worm gears can generate heat during the sliding motion, so a high-quality lubricant is essential. This type of lubricant will reduce heat and ensure optimal performance. The following tips will help you choose the right lubricant for your worm gear.

In low-speed applications, a grease lubricant may be sufficient. In higher-speed applications, it’s best to apply a synthetic lubricant to prevent premature failure and tooth wear. In both cases, lubricant choice depends on the tangential and rotational speed. It is important to follow manufacturer’s guidelines regarding the choice of lubricant. But remember that lubricant choice is not an easy task.

in Leicester United Kingdom sales price shop near me near me shop factory supplier Factory Price Electric Material Threaded Spline Threaded Shaft DC Gear Motor manufacturer best Cost Custom Cheap wholesaler

We also can design and make non-common merchandise to satisfy customers’ unique requirements. In this way, our goods have continued to obtain marketplace acceptance and customers satisfaction above the earlier number of years. we supply chromed bar and tubes for hydualic and pheumatic cylinders.

| Utilization | For new power automobile electric EPT shaft/EPT motor shaft/EPT rotation shaft/EPT spline shaft/EPT shaft/EPT shaft,and so forth |

| Specification | Length:a hundred-500mm,Outside Dia.:20-90mm,Spline module:.eight-three or EPTT |

| Surface area Treament | Anodizing/ OXiHu (West EPT) Dis.ding/ Zinc plating/ Nickel plating/ Chrome plating/ Silver plating/ EPT plating/ Imitation EPT plating/ Sand blasted/ Brushed/ Silk EPT/ Passivation/ EPTT coating/ Painting/ Alodine/ Warmth therapy/ Teflon etc. |

| Tolerance | /-.005mm or /- .0002 |

| EPT | Stainless Metal,EPTT Metal We take care of numerous other sort of materials. Please contact us if your necessary material is not listed over. |

| Inspecation EPT | Coordinate measuring machining/ Projector/ Caliper/ EPTscope/ EPTmeter/ EPT gauge/ Roughness tester/ Gauge block/ Thread gauge and so forth. |

| EPTT EPTT | 100% inspection |

| EPTT | Indeed,all are EPT according clients’ drawings design or sample |

| Our Client | BYD,EPT,Honda,GAIC Team ,SAIC group, BAIC team,Broad-EPTT,AKEI,Inovance, EPTTeEPT,and many others |

in Rayong Thailand sales price shop near me near me shop factory supplier Micro 0.5-4.5W 12V 24V Brush Brushless DC Gear Motor manufacturer best Cost Custom Cheap wholesaler

The new products incorporate a series of substantial-tech and large top quality chains and sprockets and gears, this sort of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, substantial-pace tooth chains, timing chains, self-lubrication chains, among which have sort high pace tooth chain for automobile department dynamic box and aerial chains fill in the blanks of chain in China. Total use has been produced of all types of innovative tactics and technology to get to excelsior production. EPG was awarded with “well-known product of Zhejiang Province” and “famous brand name of Zhejiang Province”. Micro .5-4.5W 12V/24V Brush/Brushless DC Equipment EPT

Item Description

24V DC EPT motor

The curtain motor

metallurgy EPT

EPT motor

| Design | Application Parameters | Rated Torque of Equipment Box | Immediate Torque of Equipment Box | Equipment Ratio | Equipment Box Duration L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Size L |

|||||||||

| Voltage | Velocity | Existing | Pace | Present | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBPD571571-16 | 24. | 472 | a hundred and ten | 419 | 295 | 512 | fifty.2 | sixty four.eight | ten thousand | 30000 | 16 | 26.four |

| ZWBPD571571-24 | 24. | 314 | a hundred and ten | 279 | 295 | 768 | 75.three | ten thousand | 30000 | 24 | ||

| ZWBPD571571-36 | 24. | 210 | 110 | 186 | 295 | 1152 | 113. | ten thousand | 30000 | 36 | ||

| ZWBPD571571-sixty four | 24. | 118 | a hundred and twenty | 105 | 295 | 1350 | 132.4 | seventy two.1 | ten thousand | 30000 | sixty four | 33.7 |

| ZWBPD571571-ninety six | 24. | seventy nine | one hundred twenty | 70 | 295 | 2571 | 198.6 | 10000 | 30000 | 96 | ||

| ZWBPD571571-144 | 24. | 52 | one hundred twenty | forty seven | 295 | 3038 | 297.nine | 10000 | 30000 | one hundred forty four | ||

| ZWBPD571571-216 | 24. | 35 | a hundred and twenty | 31 | 295 | 4556 | 446.8 | ten thousand | 30000 | 216 | ||

| ZWBPD571571-256 | 24. | 28 | one hundred twenty | 26 | 300 | 4050 | 397.two | seventy nine.4 | ten thousand | 30000 | 256 | 41 |

| ZWBPD571571-384 | 24. | 19 | a hundred and twenty | 17 | 300 | 6075 | 595.eight | 10000 | 30000 | 384 | ||

| ZWBPD571571-576 | 24. | 13 | a hundred and twenty | twelve | three hundred | 9113 | 893.seven | ten thousand | 30000 | 576 | ||

| ZWBPD571571-864 | 24. | eight | a hundred and twenty | eight | three hundred | ten thousand | 980.7 | 10000 | 30000 | 864 | ||

| ZWBPD571571-1296 | 24. | 6 | a hundred and twenty | 5 | 300 | 4500 | 441.3 | ten thousand | 30000 | 1296 | ||

above specs just for reference and customizable according to requirements.

2nd Drawing

Solution specifics show:

Software

| Smart wearable products | observe,VR,AR,XR and and so on. |

| EPT application | kitchen area EPTs, stitching EPTs, corn popper, EPT cleaner, XiHu (West Lake) Dis.Hu (West Lake) Dis.den tool, sanitary ware, window curtain, EPT closestool, sweeping robot, EPT seat, stXiHu (West Lake) Dis.Hu (West Lake) Dis. desk, electrical couch, Tv set, laptop, treadmill, spyhole, cooker hood, electric drawer, electric powered mosquito internet, EPT cabinet, EPT wardrobe, automatic cleaning soap dispenser, EPTbaby bottle sterilizer, lifting sizzling pot cookware, dishwasher, washing EPT, foodstuff breaking EPT, dryer, air conditioning, dustbin, espresso EPT, whisk,wise lock,bread maker,Window cleaning robot and and so forth. |

| conversation equipment | 5G base station,video meeting,cell cellphone and etc. |

| Business office EPT equipments | scanners, printers, multifunction EPTs duplicate EPTs, fax (FAX paper cutter), pc peripheral, lender EPT, EPT, lifting socket, show,notebook Laptop and and many others. |

| EPTmotive merchandise | conditioning damper actuator, car DVD,doorway lock actuator, retractable rearview mirror, meters, optic aXiHu (West Lake) Dis.s management system, head ligEPT beam level adjuster, auto drinking water pump, automobile antenna, lumbar assistance, EPB, automobile tail gate electrical putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, automobile seat, car charging station and and many others. |

| ToEPTand designs | radio handle design, automated cruise management, journey-on toy, instructional robot, programming robotic, medical robot, automated feeder, EPT developing blocks, escort robotic and and so on. |

| Medical equipments | blood stress meter, breath EPT, medical cleaning pump, healthcare bed, blood pressure displays, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleansing pump for orthopedic surgery,digital ciXiHu (West Lake) Dis.Hu (West Lake) Dis.ette, eyebrow pencil,fascia gun, , surgical robotic,laboratory EPT and and so on. |

| EPTs | stream manage valves, seismic screening,computerized reclosing,Agricultural unmanned aerial automobile,automatic feeEPT,EPT categorical cupboard and etc. |

| Electric powered EPT equipment | electric powered drill, screwEPTr,XiHu (West Lake) Dis.Hu (West Lake) Dis.den instrument and and so forth. |

| EPT instruments | optics instruments,automated vending EPT, wire-stripping EPT and etc. |

| Personalized treatment | tooth brush, hair clipper, electrical shaver, massager, vibrator, hair dryer, rubdown EPT, scissor hair EPT, foot grinder,anti-myopia pen, facial beauty equipment, hair roller,Electric threading knife,EPT Perfect PORE, Puff EPT,eyebrow tweezers and etc. |

| Customer electronics | digital camera, cellular phone,EPT camera, computerized retracting gadget,camcorder, kinescope DVD,headphone stereo, cassette EPT recorder, bluetooth earbEPTcharging scenario, turntable, pill,UAV(unmanned aerial car),surveillance camera,PTZ digicam, rotating smart sEPTer and and many others. |

| robots | academic robotic, programming robotic, health-related robot, escort robotic and etc. |

Our Services:

- ODM amp OEM

- EPT layout and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment

- Connected EPT support

EPT amp EPT

1) EPT Particulars

packed in EPT to begin with, then carton, and then strengthened with wood circumstance for outer EPT.

Or according to client’s requirement.

two) EPT Details

samples will be delivered inside of ten days

batch orEPTleading time in accordance to the actual predicament.

Company Info:

HangEPT EPT EPTry amp Electronics Co., Ltd was estabEPTd in 2001,We supply the overall EPT solution for buyers from design, tooling fabrication, parts production and assembly.

1) Aggressive Positive aspects

- 1) Competitive Advantages

19 year expertise in production motor EPT

We supply complex help from r ampd, prototype, screening, assembly and serial creation , ODM ampOEM

Competitive Price tag

Solution Overall performance: Lower sounds, Higher performance, EPT lifespan

Prompt Delivery: 15 working daEPTafter payment

Tiny Orders Recognized

2) Major EPT

-

EPT reduction EPT and its diameter:three.4mm-38mm,voltage:one.5-24V,EPT: .01-40W,output speed:five-2000rpm and output torque:one. gf.cm -50kgf.cm,

- Customized worm and EPT EPT EPTry

- Exact EPT motion module

- Precise element and assembly of plastic and metal powEPTEPT.

Certifications

We Have handed to maintain ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and far more…

FAQ

1. Can you make the EPT with custom technical specs?

Of course. We have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment staff, also a great term of engineers, every single of them have

a lot of operate years encounter.

two.Do you supply the samples?

Of course. Our business can offer the samples to you, and the supply time is about 5-15daEPTaccording to the specification of EPT you need to have.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the commencing of our organization, we accept tiny buy.

four. Do you have the product in stock?

I am sorry we donot have the item in stock, All items are created with orders.

5. Do you give EPT assistance?

Yes. Our firm have layout and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment crew, we can give EPT help if you

need.

six.How to ship to us?

We will ship the merchandise to you in accordance to the DHL or UPS or FEDEX and so forth account you offer.

seven.How to pay the cash?

We settle for T/T EPT. Also we have diverse financial institution account for obtaining funds, like US dollors or RMB and many others.

eight. How can I know the merchandise is suited for me?

Frist, you need to have to offer us the much more details details about the item. We will advocate the product to you according to your requirement of specification. Soon after you affirm, we will get ready the samples to you. also we will provide some very good EPTs according to your merchandise use.

nine. Can I come to your organization to go to?

Sure, you can arrive to our business to pay a visit to at whenever, and welcome to visit our company.

10. How do speak to us ?

Please send an inquiry

in Trujillo Peru sales price shop near me near me shop factory supplier 16mm Low Rpm Reduction Gear Motor for 3D Printer Equipment manufacturer best Cost Custom Cheap wholesaler

Our goods are utilized in numerous fields. EPG has set up a full established of good quality management technique which is supplied with superior inspection and check gear. Good quality and credit rating are the bases that make a company alive. 16mm lower rpm reduction EPT motor for 3D printer products and and so on.

Item Description:

Can be customized

Voltage scope: one.5 to 6V

Rating voltage: 6V

No-loading:

Velocity: 17rpm

Present: 120mA

On-loading:

Speed: 14rpm

Recent: 200mA

Torque: 729gf.cm

Output: .3W

Gear Box Size: 23.7mm

Output EPT: .01 to .5W

Gear ratio: 576:1

We also have the following objects:

| Product | Application Parameters | Rated Torque of Equipment Box | Instantaneous Torque of Gear Box | Gear Ratio | Gear Box Duration L1 |

|||||||

| Rated | At No Load | At Rated Load | All round Length L |

|||||||||

| Voltage | Velocity | Existing | Velocity | Present | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWPD016016-36 | 6. | 286 | 110 | 229 | 200 | ninety two | 9. | 33.8 | one thousand | 4000 | 36 | fifteen.1 |

| ZWPD016016-64 | six. | 161 | one hundred twenty | 129 | 200 | 108 | ten.six | 38.one | 1500 | 5000 | sixty four | 19.four |

| ZWPD016016-96 | 6. | 107 | one hundred twenty | 86 | 200 | 162 | 15.nine | 1500 | 5000 | ninety six | ||

| ZWPD016016-144 | six. | seventy one | one hundred twenty | 57 | 200 | 243 | 23.eight | 1500 | 5000 | a hundred and forty four | ||

| ZWPD016016-216 | 6. | 48 | 120 | 38 | 200 | 365 | 35.7 | a thousand | 4000 | 216 | ||

| ZWPD016016-256 | six. | 39 | 120 | 31 | 200 | 324 | 31.8 | forty two.4 | 1500 | 5000 | 256 | 23.seven |

| ZWPD016016-384 | six. | 26 | one hundred twenty | 21 | 200 | 486 | forty eight | 1500 | 5000 | 384 | ||

| ZWPD016016-576 | six. | seventeen | 120 | fourteen | two hundred | 729 | seventy one | 1500 | 5000 | 576 | ||

| ZWPD016016-864 | six. | twelve | a hundred and twenty | nine | 200 | 1094 | 107 | 1500 | 5000 | 864 | ||

| ZWPD016016-1296 | six. | 8 | a hundred and twenty | 6 | two hundred | a thousand | 98 | 1000 | 4000 | 1296 | ||

previously mentioned technical specs just for reference and customizable in accordance to needs.

Second Drawing:

Merchandise specifics demonstrate:

Software

| Sensible wearable gadgets | view,VR,AR,XR and and so on. |

| EPT software | kitchen area EPTs, stitching EPTs, corn popper, EPT cleaner, XiHu (West Lake) Dis.Hu (West Lake) Dis.den tool, sanitary ware, window curtain, EPT closestool, sweeping robot, EPT seat, stXiHu (West Lake) Dis.Hu (West Lake) Dis. desk, electric powered sofa, Television, personal computer, treadmill, spyhole, cooker hood, electrical drawer, electrical mosquito internet, EPT cupboard, EPT wardrobe, automated soap dispenser, EPTbaby bottle sterilizer, lifting scorching pot cookware, dishwasher, washing EPT, foods breaking EPT, dryer, air conditioning, dustbin, espresso EPT, whisk,smart lock,bread maker,Window cleansing robotic and and so on. |

| communication tools | 5G foundation station,online video conference,mobile phone and and so on. |

| Office EPT equipments | scanners, printers, multifunction EPTs copy EPTs, fax (FAX paper cutter), pc peripheral, lender EPT, EPT, lifting socket, display,notebook Personal computer and and many others. |

| EPTmotive items | conditioning damper actuator, automobile DVD,door lock actuator, retractable rearview mirror, meters, optic aXiHu (West Lake) Dis.s manage gadget, head ligEPT beam degree adjuster, auto h2o pump, auto antenna, lumbar assistance, EPB, vehicle tail gate electrical putter, HUD, head-up show, automobile sunroof, EPS, AGS, car window, head restraint, E-booster, auto seat, vehicle charging station and and so on. |

| ToEPTand types | radio handle product, automated cruise management, experience-on toy, educational robot, programming robotic, health care robot, automatic feeder, EPT developing blocks, escort robot and and so on. |

| Medical equipments | blood pressure meter, breath EPT, healthcare cleaning pump, medical mattress, blood stress screens, health-related ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleansing pump for orthopedic medical procedures,electronic ciXiHu (West Lake) Dis.Hu (West Lake) Dis.ette, eyebrow pencil,fascia gun, , surgical robotic,laboratory EPT and and so on. |

| EPTs | circulation management valves, seismic tests,computerized reclosing,Agricultural unmanned aerial car,computerized feeEPT,EPT categorical cabinet and etc. |

| Electric powered EPT resources | electric powered drill, screwEPTr,XiHu (West Lake) Dis.Hu (West Lake) Dis.den instrument and and many others. |

| EPT devices | optics instruments,automatic vending EPT, wire-stripping EPT and etc. |

| Individual care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown EPT, scissor hair EPT, foot grinder,anti-myopia pen, facial beauty tools, hair curler,Electrical threading knife,EPT Excellent PORE, Puff EPT,eyebrow tweezers and etc. |

| Buyer electronics | digital camera, cellular cellphone,EPT camera, automatic retracting unit,camcorder, kinescope DVD,headphone stereo, cassette EPT recorder, bluetooth earbEPTcharging case, turntable, tablet,UAV(unmanned aerial car),surveillance digital camera,PTZ digital camera, rotating wise sEPTer and and so on. |

| robots | instructional robotic, programming robotic, health care robot, escort robotic and etc. |

Our Companies:

- ODM amp OEM

- EPT style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment

- Associated EPT assistance

EPT amp EPT

1) EPT Details

packed in EPT to start with, then carton, and then strengthened with wood situation for outer EPT.

Or according to client’s necessity.

two) EPT Information

samples will be delivered inside 10 days

batch orEPTleading time in accordance to the real scenario.

Business Info:

HangEPT EPT EPTry amp Electronics Co., Ltd was estabEPTd in 2001,We give the complete EPT answer for consumers from design and style, tooling fabrication, elements producing and assembly.

1) Competitive Rewards

- one) Aggressive Advantages

19 calendar year knowledge in producing motor EPT

We supply complex assistance from r ampd, prototype, tests, assembly and serial manufacturing , ODM ampOEM

Aggressive Price tag

Merchandise Performance: Low sounds, Substantial effectiveness, EPT lifespan

Prompt Shipping and delivery: fifteen functioning daEPTafter payment

Little Orders Approved

2) Main EPT

-

EPT reduction EPT and its diameter:3.4mm-38mm,voltage:one.five-24V,EPT: .01-40W,output speed:five-2000rpm and output torque:1. gf.cm -50kgf.cm,

- Customized worm and EPT EPT EPTry

- Specific EPT movement module

- Specific ingredient and assembly of plastic and metal powEPTEPT.

Certifications

We Have passed to keep ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and a lot more…

FAQ

one. Can you make the EPT with customized technical specs?

Of course. We have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment staff, also a wonderful time period of engineers, each of them have

a lot of perform several years knowledge.

two.Do you supply the samples?

Indeed. Our organization can give the samples to you, and the delivery time is about five-15daEPTaccording to the specification of EPT you want.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the starting of our enterprise, we take modest order.

4. Do you have the item in inventory?

I am sorry we donot have the item in stock, All products are created with orders.

5. Do you offer EPT support?

Indeed. Our firm have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment staff, we can provide EPT support if you

need.

6.How to ship to us?

We will ship the items to you according to the DHL or UPS or FEDEX and so on account you supply.

seven.How to shell out the cash?

We accept T/T EPT. Also we have different bank account for receiving funds, like US dollors or RMB and so forth.

8. How can I know the merchandise is ideal for me?

Frist, you need to provide us the far more particulars information about the product. We will advise the merchandise to you according to your prerequisite of specification. Following you affirm, we will put together the samples to you. also we will offer some great EPTs in accordance to your merchandise use.

nine. Can I come to your company to visit?

Sure, you can arrive to our company to pay a visit to at whenever, and welcome to check out our firm.

ten. How do speak to us ?

Please ship an inquiry

B-28 made in China – replacement parts – in Lubango Angola Nylon Sleeve Gear Coupling for Motor Generator Sets Pump Sets with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For a lot more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Our items are widely utilised in health care, armed forces, agriculture, marine, industry, hydraulic,auto, bike, electron, optics, instrument, communication, nuclear, chemical, Petrochemical, vitality, foodstuff market and so forth.

Characters of nylon-sleeve:

one. Excellent mechanical properties

two. No brittlement at low temperature

3. Good slippery and frictional properties

4. Excellent electrical insulation

five. Resistance to chemical corrosion

six. High accuracy of machining

Programs:

Mainly used in the mining, metallurgical, cement, substances, development, building materials,

Electric power, telecommunications, textiles, and transportation departments.

Such as:

1. EPT Belt conveyor, AFC conveyor, chain conveyor, screw conveyor.

two. Pump: Water pump, oil pump, slush pump, and so forth.

three.Enthusiast:Draft fan,enthusiast,boil fan,etc.

4. Excavator: Bucket excavator, bucket wheel excavators, bucket wheel stacker reclaimer.

5. Crane: Tower crane, gantry crane, bridge crane.

six. Others: Various elevators, coal plough, ball mill, crusher, recreation machine.

seven. Blender equipment, centrifuge, washer, leather-based-making machine, machine for recreation

park mixer wire drawing machine. Extruder, and dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, and many others.

Workshop

EPT merchandise

About us

HangZhou HangZhouANG Equipment Co., Ltd. With a historical past of more than twenty several years, is specialized in producing sprocket, equipment, coupling, taper bush and EPT transmission items.

The firm was launched in 1993 and at the moment employs a lot more than 100 individuals. It covers an spot of eighteen, 000 sq. meters, with a lot more than 250 sets of a variety of sorts of metallic processing gear, including 90 sets of CNC equipment.

We adopt the pursuing common to create our items: ISO 606 ANSIB 29.1 DIN 1801 GB 124-ninety seven.

Our products are exported to far more than sixty international locations and locations, including U. S. A, Japan, Germany, Italy, Argentina, South Africa.

Sprocket is our primary items for exporting. We can provide you numerous kinds of sprocket, Pitch size from 1/4″ to 4″ and tooth No. From 8 to a hundred and fifty.

We often provide our clients competitive price tag, outstanding high quality and prompt shipping. We usually think about customer’ S demands very first. Our goal is: “Customer’ S fulfillment is our pursuit”.

We sincerely hope to set up prolonged-term business relations with every customized on the foundation mutual benefits and friendship.

The use of unique gear manufacturer’s (OEM) part figures or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the listed alternative parts contained herein are not sponsored, accepted, or made by the OEM.

Best China manufacturer & factory K in Santo Domingo Dominican Republic Series helical-bevel gear box with AD k series gear ratios small 90 degree gearbox motor Speed Reducer dodge transmission With high quality best price

Provider & High quality controlWe supply in depth drawings and offer you each time required.

A seal-journal surface area that functions an inverted shot-peened texture, with lifted (fairly than indented) spherical lobes and corresponding valleys in among, far better supports hydrodynamic lubrication. EPT created a approach that compresses seal journals among burnishing dies that have been peened to produce random spherical depressions. This leaves an “orange peel” texture on the journal floor, usually with a twenty to forty-m in. floor roughness.

Overview

Fast Specifics

- Relevant Industries:

-

Hotels, Garment Stores, Constructing Content Shops, Manufacturing Plant, Equipment Repair Shops, farms, cafe, Residence USE, Retail, Meals Shop, Printing Retailers, Power & Mining, Foods & Beverage Outlets, Advertising Firm, Construction performs

- Location of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

ten~62800N.m

- Enter Velocity:

-

1450/960rpm

- Output Pace:

-

fourteen-280rpm

- Ratio:

-

five.36~197.37

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

LYC, HRB,ZWZ,NSK

Source Capacity

- Provide Capacity:

- five hundred Unit/Units for every Thirty day period

Packaging & Shipping

- Packaging Information

- Wood boxes , Cantons packed in 1 pallet

AT collection with tri-lobe tube (triangular) The triangular tube condition is the most used, from light-weight to relatively large applications. In the circumstance of programs with substantial sliding, the R variation with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Amount(Boxes) 1 – 1 >1 Est. Time(days) twenty To be negotiated

On the web Customization

Merchandise Description

K Sequence helical-bevel gear box with Advertisement k series equipment ratios tiny 90 degree gearbox motor Velocity Reducer dodge transmission

SLK sequence gearbox is one particular type of Helical Bevel variety gearbox , Large-stainless solid iron case . ,it is made based mostly on modularization , which provide a lot of variation kinds of mixtures ,mounting varieties ,and composition styles .The element classification of ratio can fulfill various of functioning condition .Large Transmission efficiency ,Minimal strength intake, exceptional overall performance . The difficult tooth surface equipment use the large high quality alloy metal , the procedure of carburizing and quenching, grinding ,which give it adhere to figures : Stable transmission , lower noise and temperature ,substantial loading ,extended functioning life. which broadly use for industry tools of metallurgy ,Creating Content , Chemical , Mining , Oil, Transportation , Papermaking , Sugar generating , engineering Equipment ,and many others

Requirements:

one) Output speed: .6~1,028r/min

2) Output torque: up to 21700N.m

3) Motor electricity: .twelve~200kW

4) Mounted sort: foot-mounted and flange-mounted mounting

|

Product Identify |

SLK Sequence Rigid Tooth helical bevel reducer |

|

Equipment Substance |

20CrMnTi |

|

Circumstance Materials |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding complete by HOFLER Grinding Equipment |

|

Color |

Tailored |

|

Sounds Examination |

65~70dB |

|

Effectiveness |

ninety four%~98% (relies upon on the transmission phase) |

|

Lubricating oil |

Shell Omala artificial oil or mineral oil , or comparable brand |

|

Heat treatment |

tempering, cementiting, quenching,and so forth. |

|

Brand name of bearings |

C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Brand of oil seal |

NAK or other brand name |

|

Temp. increase (MAX) |

40 ° |

|

Temp. rise (Oil)(MAX) |

50 ° |

|

Vibration |

≤20µm |

Merchandise Display

Good quality Manage

We warmly welcome the pals from all the entire world!Higher good quality Gear Grinding

The gears are taken grinding complete to make positive the long existence

Gear Examination

Gears are taken inspection examination to make certain they are certified for assembling

Large quality Gearbody

Equipment bodies processed by our new imported CNC facilities,make sure the large precision and cleanse end

Our Business

Factory

Our Manufacturing facility

Workshop

Our Workshop

Packing & Shipping

Packing Particulars : Packing, sound bicycle saddle, 50pcs/carton

Shipping and delivery Details : 3-30 days right after buy of Reliable bicycle tire tubes

1. Specific logistics packaging

two. Suitable carton dimensions

three. Shock bubble film

four. Skilled placement

five. Skilled shock

six. Total package

Our Certifications

FAQ

Q: Are you investing organization or company ?

A: We are manufacturing unit.

Q: How lengthy is your shipping and delivery time?

A: Usually it is 5-10 days if the goods are in stock. or it is fifteen-20 days if the items are not in stock, it is in accordance to quantity.

Q: Do you offer samples ? is it cost-free or extra ?

A: Of course, we could offer the sample for free of charge charge but do not spend the price of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,harmony just before shippment.

If you have an additional question, pls truly feel free to speak to us as beneath:

Make contact with

Mobile 5hp induction motor price wholesaler made in China – replacement parts – in Sao Jose dos Campos Brazil Phone Camera Small Stepper Worm Gear Motor with top quality

We – EPG Group the greatest worm gearbox, couplings and gears factory in China with 5 different branches. For much more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

Mobile Phone Digicam Modest Stepper Worm Gear Motor

Merchandise Description

1)Specification

Product: ZWPD006006-700

Rated Voltage: 3.0v

No Load Speed: 102 rpm

No Load Current: 90 mA

Rated Load Speed: 40 rpm

Rated Load Current: 100 mA

Rated Load Torque: 60 gf.cm

Rated Torque of Equipment Box: sixty gf.cm

Instant Torque of Equipment Box: one hundred twenty gf.cm

General Length L: 21.05 mm

Gear Box Size L1: 11.seventy five mm

| Design | Application Parameters | Rated Torque of Equipment Box | Instant Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Length L |

|||||||||

| Voltage | Speed | Recent | Velocity | Existing | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWPD006006-seven-hundred | 3. | forty six | 60 | 40 | one hundred | sixty | 5.88 | 21.05 | sixty | 120 | seven hundred | eleven.seventy five |

previously mentioned technical specs just for reference and customizable according to demands.

2)Application

|

Audio and visible equipments |

notebook Personal computer, camcorder, automobile DVD, kinescope DVD, vehicle CD player, camera, electronic digital camera, headphone stereo, cassette tape recorder and etc. |

|

Home software |

electric shaver, tooth brush, kit ept appliances, hair clipper, sewing devices, massager, vibrator, hair dryer, rubdown device, corn popper, scissor hair machine, vacuum cleaner, backyard resource, sanitary ware, window curtain, coffee machine, whisk and etc. |

|

Office automation equipments |

CD-ROM, OA equipments, scanners, printers, multifunction machines duplicate equipment, fax, FAX 13083988828 paper cutter, pc peripheral, lender machine and and so forth. |

|

Automotive products |

conditioning damper actuator, door lock actuator, retractable rearview mirror, meters, optic axis handle system, head light beam degree adjuster, auto drinking water pump, auto antenna, lumbar help, automatic vending machine and and many others. |

|

Toys and versions |

radio manage product, automated cruise management, journey-on toy and and many others. |

|

Health care software |

blood force meter, breath machine and and so forth. |

|

Industrials |

air freshener, display, circulation management valves and etc. |

|

Electrical energy equipment |

electric powered drill, screwdriver and and so forth. |

|

Precision instruments |

monitor, optics instruments and and so on. |

Our Providers:

- ODM & OEM

- Gearbox style and improvement

- Relevant technology assist

Packaging & Shipping

1) Pac ept Particulars

packed in nylon first of all, then carton, and then bolstered with wood circumstance for outer packing.

Or according to client’s necessity.

2) Shipping Information

samples will be shipped in 10 days

batch purchase major time in accordance to the genuine circumstance.

Business Info:

HangZhou ept Equipment & Electronics Co., Ltd was established in 2001,We provide the complete drive solution for clients from style, tooling fabrication, factors production and assembly.

1) Aggressive Positive aspects

- one) Competitive Benefits

17+calendar year encounter in producing motor gearbox

We provide technological support from r&d, prototype, screening, assembly and serial production , ODM &OEM

Competitive Price

Product Overall performance: Low sound, Higher performance, Long lifespan

Prompt Supply: 15 wor ept days soon after payment

Little Orders Approved

2) Main Items

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,electricity: .01-40W,output velocity:5-2000rpm and output torque:1. gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery

- Precise electromechanical motion module

- Specific component and assembly of plastic and metallic powder injection.

Certifications

We Have passed to keep ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and far more…

FAQ

1. Can you make the gearbox with personalized requirements?

Sure. We have design and style and growth staff, also a fantastic time period of engineers, every of them have

numerous function years experience.

two.Do you give the samples?

Of course. Our organization can supply the samples to you, and the delivery time is about 5-15days in accordance to the specification of gearbox you need.

three.What is your MOQ?

Our MOQ is 2000pcs. But at the starting of our enterprise, we settle for tiny buy.

4. Do you have the item in stock?

I am sorry we donot have the product in stock, All items are created with orders.

5. Do you give technologies help?

Indeed. Our company have design and style and growth staff, we can offer engineering assist if you

need.

six.How to ship to us?

We will ship the items to you in accordance to the DHL or UPS or FEDEX and so forth account you supply.

7.How to spend the cash?

We take T/T in advance. Also we have various lender account for getting money, like US dollors or RMB and so on.

eight. How can I know the item is suitable for me?

Frist, you want to offer us the more information information about the item. We will advocate the merchandise to you according to your necessity of specification. Right after you validate, we will prepare the samples to you. also we will offer you some great advances according to your item use.

9. Can I come to your organization to pay a visit to?

Yes, you can come to our business to pay a visit to at at any time, and welcome to pay a visit to our organization.

10. How do speak to us ?

Please send an inquiry

/ The use of original gear manufacturer’s (OEM) portion numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our business and the outlined substitute elements contained herein are not sponsored, accepted, or made by the OEM. /

Best China manufacturer & factory china manufacturer factory of Worm Gear Reducer Used in Mining Water Conservancy Motor With high quality best price

PersonnelOur sales persons are well trained to accommodate your requests and speak English for your convenience.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Application:

-

Mining

- Weight:

-

0.4-45kg

- Rated Power:

-

0.12-200 KW

- Color:

-

Customer Request

- Material:

-

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

Cast Iron

- Certification:

-

ISO9001

- Mount Position:

-

Foot Mounted. Flange Mounted

- SHIPPING:

-

Express

- MOQ:

-

1pcs

- Quality:

-

High Precision

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1 2 – 10 >10 Est. Time(days) 5 13 To be negotiated

Online Customization

Products Description

NMRV gearbox

NMRV reducer is a new type of reducer, also known as RV reducer. “NMRV” is a general term, it refers to the aluminum reducer, the world has been used to aDressing grinding wheels leaves a microscopic surface “thread” which, under the right conditions, can transfer to the seal journal and create a leak path.luminum reducer called “NMRV reducer”. The main components are oil seal, oil plug, worm gear box, ball bearing, output shaft, worm wheel, worm, output shaft, motor disk (flange), output shaft cover, hexagon socket head screw, double round key, gasket, etc. BHADE reducer, one of NMRV series, has single flange input, flange output or double shaft output.

- Characteristics

The weight of NMRV reducer is relatively light, the shell is made of aluminum alloy, which has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long serClose up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. vice life, noiseless movement and other advantages, convenient and simple connection with the motor. NMRV reducer is a kind of practical transmission equipment, and its appearance design and its integration are more in line with public demand than other types of reducer. Although the RV reducer made of aluminum alloy only emerged in 2007, its application field and popularity are even more superior than other types of reducer. It is a kind of reducer with high practicability and a fusion of advanced technologies at home and abroad. NMRV reducer is very convenient to connect with ordinary motor, stepless gearbox and flanged electromagnetic clutch brake set. No coupling is needed. Can be suitable for all – round installation, and the output torque is also relatively large, work fairly smooth and so on.

|

NMRV-030-30-VS-AS-80B5-0.75KW-B3 |

||

|

NMRV |

worm gearbox |

|

|

NRV |

worm gearbox (with input shaft) |

|

|

030 |

products type ; worm gearbox center dictance |

|

|

30 |

reduction ratio |

|

|

VS |

double input shaft |

|

|

AS |

single input shaft |

|

|

80B5 |

motor mounting facility |

|

|

0.75kw |

motor power |

|

|

B3 |

mounting position |

|

Details Images

COMPANY

OUR COMPANY

We are a manufacturer in ZJ Province, China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Certifications

Packing & Delivery

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZJ Province, China. Our company owns

the ability of manufacturing, processing, designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry,

we will recommend the products’ models upon synthesizing the factors of

field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order,

we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A: We will reply as soon as possible, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining

equipment, automation equipment, food machinery, packaging equipment,

tobacco equipment and so on.

Best China manufacturer & factory factory manufacturer for custom cnc machining helical tooth metal steel casting iron bronze worm gear for servo motor With high quality best price

The product well displays environmental protection and energy saving.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Surface treatment:

-

Plating,According to the drawing

- Heat treatment:

-

Quenching,Nitriding,According to the product

- Processing:

-

Gear Hobbing, Milling, Shaping, Broaching,Shaving, Grinding

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Tolerance:

-

Outer Diameter Length Dimension

- Module:

-

M1-M8

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand

The company was certified by ISO9001:2008 Quality Management System.

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 15 To be negotiated

The PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HP

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

custom cnc machining helical tooth metal steel casting iron bronze worm gear for servo motor

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS169Worm Gears A worm gear system consists of a worm and worm wheel positioned as a cross axis and is the most compact type of gear system. Due to the compact design, worm gear reducers are able to be placed in relatively small spaces and provide high-ratio speed reduction. Worm gears are known to run smoothly and quietly, as long as they are properly mounted and lubricated.49:2009 |

Product Photos :

Packaging & Shipping