Product Description

Product Description

Introduction of Commodity

Cold drawn steel is a kind of steel processed by cold drawing process. It has high strength and hardness and is widely used in various fields.

Cold drawn steel has high strength and hardness, is widely used in machinery manufacturing, automobile industry, electronic and electrical, aerospace and construction fields.Cold drawn steel is processed by cold drawing process, which has good mechanical properties and surface quality. It can meet the requirements of material strength, durability and accuracy in different fields, and provides a reliable material basis for all walks of life.

Product Parameters

| Product name | Cold drawn steel stainless bright precision bars | |

| Material | 304,304L,309S,310S,316,316L,316Ti,317,317L,321,347H,201,202,405,409, | |

| 410,420,430,etc | ||

| Type | Round, square, hexagonal, flat,angle | |

| Surface | Bright, Polishing | |

| Specification | Round bar | Diameter: 1mm~500mm |

| Angle bar | Size: 3mm*20mm*20mm~12mm*100mm*100mm | |

| Square bar | Size: 4mm*4mm~100mm*100mm | |

| Flat bar | Thickness: 2mm~100mm Width: 10mm~500mm | |

| Hexagonal | Size: 2mm~100mm | |

| Shape | Round/Square/Rectangular or Customized | |

| Technical | Cold Drawn | |

| Color | Silver White | |

| Origin | ZheJiang , China | |

| Surface Treatment | Polished | |

| Price Term | CIF, CFR, Fob, EXW | |

| Transportation | FCL, LCL | |

| Certificate | API,ISO,SGS,BV,CE etc | |

| Delivery Time | 7-14days | |

| Warranty | 1 year | |

| MOQ | 1000 kilograms | |

| Payment Item | 30% TT deposit+70% TT against copies of original files. | |

| Application | Manufacturing industry, Architectural decoration, furniture, Chemical industry, Electronics industry, Medical devices, Environmental protection field etc. | |

Products Display

Company Profile

Xinruyi Steel Group was built in year 2017 with registered capital of 30,000,000RMB, and we have been in the steel products industries for more than 10years. The group is located in HangZhou City, next to capital of ZheJiang Province, and it enjoy good transportation environment of 3 hours to nearest port and 1 hour CZPT the airport.

As it is well known to all, HangZhou city is the biggest steel pipe base in North China, with this significant advantage on geography aspect, us company have developed into 1 modern international CZPT STEEL GROUP. Till now we have 2 production plants for steel pipes and plate series production and processing, and 3 warehouses for steel products. Our yearly production scale can be reach to 500,000tons, and our warehouse stocks is yearly above 20,000tons. So that we can meet all kinds of demands from different countries clients. Our salesmen are trained to get the best and professional skills on doing export trading dealing with various kinds of issues in the trading, which is a base that our buyers can have good buying experience. Till now we can supply the good quality products consisting of and not limit to the following, steel pipes, bars, rock bolts, guardrail composite pipe, guardrail board, color coated steel coils, galvanized coils, steel balls, steel chains, steel plates and steel bearing. Besides we can provides processing procedures for the steel products, like anti-rust protecting, cutting and chamfer, coupling, heat treating, bending, galvanizing, polishing, beveling, pickling, plastic spraying, CNC machining, and so on.

With efforts of CZPT People we have the pleasure to serve the clients from more than 20 countries and areas, We earned good reputations from the clients without any claim. We finally become good friends and intimate partners with them.

Looking forward, we get good confidence that we will expand our business scales to more countries and areas, and serve more people in the world. Because we always believe quality of the commodity is the life of company, stability is the essence of quality. Also the integrity in business will help bring the long term business relationship, so it is the code that 1 company can develop and survive.

Xinruyi Group is looking CZPT to the cooperation with you! We believe 1 time cooperation, friends forever!

(Xinruyi Steel Group Swear: we do not cheat any of our client, we only do business with good faith and honesty! CZPT will NEVER offering incredible low rate to attract clients and sending less weight goods to make money. )

(Xinruyi Steel Group Swear: Even if we do not get the order, we do not cheat even 1 client!)

(We give Made-in-China complain center as below: complaint/)

Insepction And Testing

Featured Products

Certifications

*What is your paying terms?

Our usual paying terms are 30%TT as deposit and balance paid after seeing copy of bill of loading. For clients cooperated for more than 1 year, we accept 20% prepay. Beside we do business also under D/P and LC terms.

*How long is your delivery time?

For the goods we have in stocks, we deliver the goods within 5days. If it is a production order with volume not above 200tons, the delivery time will usually be within 20days after sealing contract. And the delivery time shall be slightly longer for order volume above 200tons.

*Can you do partial shipment?

We will follow client request to do partial shipment or not. Partial shipment is not a problem for us.

*What is your Minimum Order Quantity?

For goods in stocks we supply starting with 1 piece. Shall it is a production order, the MOQ is 3tons. Please be noted price based on MOQ will be slight higher than FCL condition due to higher unit cost.

*Before cooperation we want a sample for inspecting of quality, is that okay?

We can provide a free sample for you shall sample value not above 30USD, you only need to pay the express charge. For a sample valued more than 30USD, the express charge and just 1 half of sample value is on the account of you, and we afford the other half.

*What is the mode of transportation?

Ocean freight is the most important shipping way, and we choose the ship line based on soonest and earliest shipping time, rather than cheaper cost; or we follow clients’ instruction if there is one. Also railways will be chosen by us when it is more convenient. For samples and papers, the transportation will be by air.

FAQ

1.What is your paying terms?

Our usual paying terms are 30%TT as deposit and balance paid after seeing copy of bill of loading. For clients cooperated for more than 1 year, we accept 20% prepay. Beside we do business also under D/P and LC terms.

2.How long is your delivery time?

For the goods we have in stocks, we deliver the goods within 5days. If it is a production order with volume not above 200tons, the delivery time will usually be within 25days after sealing contract. And the delivery time shall be slightly longer for order volume above 200tons.

3.Before cooperation we want a sample for inspecting of quality, is that okay?

We can provide a free sample for you shall sample value not above 30USD, you only need to pay the express charge. For a sample valued more than 30USD, the express charge and just 1 half of sample value is on the account of you, and we afford the other half.

4.Does your company accept third party inspection?

The answer is yes. Especially for new client, they have concern on product quality and quantity, so they authorized the third party inspection like SGS and BV several times to inspect the goods in stead of them, and we coordinated with their work well.

5.Do you accept annual supply order?

Some of our clients purchase annually. They may place order at beginning or certain time of year, however they need us to supply the goods every month or every season. We can do and accept this kind of supplying. We do not ask for the storage charge, however some percentage of deposit will be with us.

6.What documents do you supply for each order?

The documents will usually consist of Original Packing List, Commercial Invoice, Mill Test Certificate, Certificate of Origin, Insurance Policy, and Bill of Loading. Some other documents will be as per client request.

Finally we thank you again that you can visit CZPT Steel, please send your inquiry or comments freely.

We wish you always a beautiful day and in good health!

| Type: | Stainless Steel Bars |

|---|---|

| Standard: | ASTM, AISI, GB, JIS |

| Grade: | 200,300,400 Series and Duplex Steel |

| Certification: | ISO, GB |

| Shape: | Round |

| Technique: | Cold-Drawing |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

How do drive shafts handle variations in speed and torque during operation?

Drive shafts are designed to handle variations in speed and torque during operation by employing specific mechanisms and configurations. These mechanisms allow the drive shafts to accommodate the changing demands of power transmission while maintaining smooth and efficient operation. Here’s a detailed explanation of how drive shafts handle variations in speed and torque:

1. Flexible Couplings:

Drive shafts often incorporate flexible couplings, such as universal joints (U-joints) or constant velocity (CV) joints, to handle variations in speed and torque. These couplings provide flexibility and allow the drive shaft to transmit power even when the driving and driven components are not perfectly aligned. U-joints consist of two yokes connected by a cross-shaped bearing, allowing for angular movement between the drive shaft sections. This flexibility accommodates variations in speed and torque and compensates for misalignment. CV joints, which are commonly used in automotive drive shafts, maintain a constant velocity of rotation while accommodating changing operating angles. These flexible couplings enable smooth power transmission and reduce vibrations and wear caused by speed and torque variations.

2. Slip Joints:

In some drive shaft designs, slip joints are incorporated to handle variations in length and accommodate changes in distance between the driving and driven components. A slip joint consists of an inner and outer tubular section with splines or a telescoping mechanism. As the drive shaft experiences changes in length due to suspension movement or other factors, the slip joint allows the shaft to extend or compress without affecting the power transmission. By allowing axial movement, slip joints help prevent binding or excessive stress on the drive shaft during variations in speed and torque, ensuring smooth operation.

3. Balancing:

Drive shafts undergo balancing procedures to optimize their performance and minimize vibrations caused by speed and torque variations. Imbalances in the drive shaft can lead to vibrations, which not only affect the comfort of vehicle occupants but also increase wear and tear on the shaft and its associated components. Balancing involves redistributing mass along the drive shaft to achieve even weight distribution, reducing vibrations and improving overall performance. Dynamic balancing, which typically involves adding or removing small weights, ensures that the drive shaft operates smoothly even under varying speeds and torque loads.

4. Material Selection and Design:

The selection of materials and the design of drive shafts play a crucial role in handling variations in speed and torque. Drive shafts are typically made from high-strength materials, such as steel or aluminum alloys, chosen for their ability to withstand the forces and stresses associated with varying operating conditions. The diameter and wall thickness of the drive shaft are also carefully determined to ensure sufficient strength and stiffness. Additionally, the design incorporates considerations for factors such as critical speed, torsional rigidity, and resonance avoidance, which help maintain stability and performance during speed and torque variations.

5. Lubrication:

Proper lubrication is essential for drive shafts to handle variations in speed and torque. Lubricating the joints, such as U-joints or CV joints, reduces friction and heat generated during operation, ensuring smooth movement and minimizing wear. Adequate lubrication also helps prevent the binding of components, allowing the drive shaft to accommodate speed and torque variations more effectively. Regular lubrication maintenance is necessary to ensure optimal performance and extend the lifespan of the drive shaft.

6. System Monitoring:

Monitoring the performance of the drive shaft system is important to identify any issues related to variations in speed and torque. Unusual vibrations, noises, or changes in power transmission can indicate potential problems with the drive shaft. Regular inspections and maintenance checks allow for the early detection and resolution of issues, helping to prevent further damage and ensure the drive shaft continues to handle speed and torque variations effectively.

In summary, drive shafts handle variations in speed and torque during operation through the use of flexible couplings, slip joints, balancing procedures, appropriate material selection and design, lubrication, and system monitoring. These mechanisms and practices allow the drive shaft to accommodate misalignment, changes in length, and variations in power demands, ensuring efficient power transmission, smooth operation, and reduced wear and tear in various applications.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Are there variations in drive shaft designs for different types of machinery?

Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery:

1. Automotive Applications:

In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements.

2. Industrial Machinery:

Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery.

3. Agriculture and Farming:

Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris.

4. Construction and Heavy Equipment:

Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation.

5. Marine and Maritime Applications:

Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels.

6. Mining and Extraction Equipment:

In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear.

These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

editor by CX 2023-12-14

Mining wholesaler made in China – replacement parts – in Jamnagar India Used Heavy Duty Conveyor Idler Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Belt EPT system Drive pulley conveyor drum

Product Description

1,This series Drive rollers are welded by steel plate, and using rolling bearings.

2,The surface of drive plulley includes three type: smooth, plastic and ca EPT plastic. Usually the smooth pulley can be used on condition that the power is not big, and the the ambient temperature is low. The plastic surface pulley should be used when it is easy to slip.

The quality of ca EPT plastic pulley is better.Becasue the external surface layer is wear-resistant. The packed plastic drum can achieve the same performance. It’s easy to replace rubber surface , easy to maintain.And it’s also be considerde affordable and durable.

3,Please refer to the following table for each bandwidth of the roller.

4,The diameter selection of entire core plastic conveyor belt drive pulley is same as the same intensity rubber conveyor belt.

| B(mm) | 500 | 650 | 800 | 1000 | 1200 | 1400 |

| D(mm) |

500 | 500 | 500 | 630 | 630 | 800 |

| – | 630 | 630 | 800 | 800 | 1000 | |

| – | – | 800 | 1000 | 1000 | 1250 | |

| – | – | – | – | 1250 | 1400 |

flat belt idler pulley

flat belt idler pulley for belt conveyor is used with electric motor

to drive the belt to moving.

1.Key Features of flat belt idler pulley

(1).Steady running, reliable quality and reduce maintenance;

(2).Less movement longitudinally, rotating smoothly, extends the life span;

(3).Various bearing housing and sealing structure are available for the customers choice;

(4).Multipass labyrinthine sealing,preventing the mixed dirt and water immersed;

(5).Manufacturing by steel pipe specially for of high precision roller, ensuring the strong load,

low shaking and less noise.

2.Components of flat belt idler pulley

(1)High quality raw material: Q235 / Q 245 / Mn steel plate.

(2)Bearing: LYC, HRB, NTN, etc.

(3)Long service life (about 8 years).

(4)It can work in the dusty, wet, muddy or other harsh environments.

(5)Welding: Mixed gas TIG.

(6)Surface: painting or rubber coated.

(7) Lubrication: Lithium grease, rust inhibitor.

3.Production of flat belt idler pulley

| Parameter of flat belt idler pulley | |||

| Type | Belt width(mm) | Standard diameter(mm) | Length(mm) |

| Driving idler pulley |

500 | 500 | Length of pulley depends on the width of conveyor belt |

| 650 | 500~630 | ||

| 800 | 630~1000 | ||

| 1000 | 800~1150 | ||

| 1200 | 800~1150 | ||

| 1400 | 1000~1350 | ||

| 1600 | 1150~1600 | ||

| 1800 | 1150~1800 | ||

| 2000 | 1350~2000 | ||

| 2200 | 1600~2200 | ||

| 2400 | 1800~2400 | ||

Certificate: ISO, CE

Type conveyor DTII, TD75

Bearing NO: 6204/6205//6306/6307/6308 etc

Material: carbon steel, Rubber coated

Belt width: from 300mm to 2400mm

The international Market: Middle east, South America, Africa, Southea EPT Asia. Etc.

Packaging & Shipping

About flat belt idler pulley package

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

China Chain and sprocket factory : Conveyor 428 Roller Chain in Davao City Philippines Belt Drive Pulleys and Motorized Pulley with ce certificate top quality low price

We – EPG Team the largest Chain and agricultural gearbox manufacturing facility in China with 5 different branches. For a lot more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

If you are fascinated in any of our items or would like to discuss a possible purchase, please really feel cost-free to get in touch with us. ISO our goods are promoting effectively in the American, European, South American and Asian markets. a specialised supplier of a total range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….9001:2015 licensed producer and distributor of roller chains. Varieties of roller chains consist of ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, cost-free-flow chains, specialty chains and British standard chains. ASME/ANSI common chains are accessible in huge and little pitch, double pitch and leaf types. Roller chains are employed in food packaging, forklift vehicles, oilfield drilling, bikes, conveyors and electricity transfer apps. corrosion- and put on-resistant coiled tubing injector roller chain assemblies for the oil and fuel industries. Available in one and double pitch generate chain varieties with different sizes and power score. Features include zinc-nickel and non-hexavalent chromate protecting exterior coating, electrochemically bonded, and interference match cover plates. EPT belt push pulleys and motorized pulley

Huayue EPT Pulley Specification&colon

1&interval Pulley Diameter&colon 250-1800mm&interval

two&time period Belt width&colon 300mm to 2400mm&period

three&time period Duration&colon Depend on the belt width&period of time

4&interval Welding&colon Carbon dioxide arc welding&comma argon arc welding&comma electrode welding and so on&time period&semi In accordance with AWS stHangZhourd or substitute welding stHangZhourd

5&interval Lagging&colon Cold lagging&semi Very hot vulcanized lagging&comma ceramic lagging

six&period Pulley tube materials&colon Q235 seamless carbon steel&time period

7&interval Professional pulley manufacturing line&period of time

8&period of time Skilled designing and inspection group&interval

nine&time period Certification&colon ISO&comma BV&comma etc

Kind of EPT Pulley&colon

EPT tail pulley

EPT head pulley

EPT rubber lagging pulley

EPT steel pulley

EPT driving pulley

EPT turnaround pulley

Sample conveyor pulley

EPT pulley

Rubber conveyor pulley

Head pulley and so on&time period

EPT Head Tail pulley&colon

Head pulley can be divided into driving pulley &lparhead pulley&rpar and thurn about pulley &lpartail pulley&rpar&comma driving pulley is the principal portion for transmitting the electricity&colon Sleek area and rubber surface&comma and rubber area can be categorised into clean rubber surface&comma herringbone rubber area and diamond rubber area to meet diverse technical demands&time period Averting pulley can be categorised into smooth rubber floor and smooth metal floor&time period

Design

All the pulley adopt integrated bearing housing which is lubricated and loaded with grease and has two varieties&colon Iron casting and steel casting&comma the shaft is manufactured of forty five&numsteel&comma the shell adopt weld assembly&interval

Our be EPT good quality dependent on&colon

Company

Expertise in Cooperate with EPT five hundred Firms

Expert EPT Capacity

Secure Quality

Sensible Price tag

Little Orders Accepted

Continuous Enhancements

Higher Product Performance

Prompt Shipping

Specialist Support

For far more information&comma you should inquiry us&excl

Polyester conveyor belt&comma &lparEP&rpar

Nylon conveyor belt&comma &lparNN&rpar

Cotton conveyor belt&comma &lparCC&rpar

Sidewall conveyor belt &lparSW&rpar

Metal Cord conveyor belt &lpar EPT &rpar

Chevron conveyor belt&comma &lparC5 C10 and C15&rpar

Oil Resistance conveyor belt&comma &lparOR and MOR&rpar

Hot Resistance conveyor belt&comma &lparHR&rpar

Fireplace Resistance conveyor belt&comma &lparFR&solPVC&solPVG&rpar

Heat Resistance conveyor belt&comma &lparHR&sol FR&rpar

Chilly Resistance conveyor belts&comma &lparCR&rpar

Sample conveyor belt &lpar thirty&plus Moulds&rpar

Metal Mesh conveyor belt &lparHeat resistant temp until 800c&rpar

Countless belts

EPT roller&comma loafer

EPT Pulley&comma frame&comma bracket and so on

| Type | Belt width (mm) | StHangZhourd Diameter(mm) | Length (mm) |

| Drive Head Pulley | five hundred | 500 | Length of the pulley depends on the belt width of the conveyor |

| 650 | 500, 630 | ||

| 800 | 500, 630, 800 | ||

| a thousand | 630, 800, 1000 | ||

| 1200 | 630, 800, 1000 | ||

| 1400 | 800, 1000 | ||

| Tail Pulley | five hundred | 250, 315, 400, 500 | |

| 650 | 250, 315, 400, 500 | ||

| 800 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1000 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1200 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1400 | 250, 315, 400, 500, 630, 800, 1000 |

The use of original products manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our business and the shown substitution parts contained herein are not sponsored, accredited, or created by the OEM.

Machinery manufacturer made in China – replacement parts – in Aleppo Syrian Arab Republic Spare Parts Iron Casting Belt Pulley with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 diverse branches. For far more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

manufacturing particulars:

| belt pulley: | |

| one) Molding method: | Resin sand/Inexperienced Sand/Expense Casting |

| two) Content: | EN-GJS-400-15/ EN-GJS-450-ten/EN-GJS-500-7/EN-GJS-600-3. GGG40, GGG50, GGG60. |

| 3) Molding: | Hand molding/Molding machine/Molding line. |

| four) Achievable Heat Treatment: | Annealing. |

| five) Sector associated: | Municipal business/Construction industry/ Fluid market/Automotive market |

| 6) Element device excess weight selection: | 2kg-3000kgs |

| 7) Max/Min wall thickness specifications: | 5mm-250mm |

| eight) Company Certification: | ISO9001(2000)/ TS16949 |

Why Choose Us

one) Experience in casting for above fifteen many years and served consumers all about the planet.

2) Regular substance according to specialized drawing

3)Steady high quality

four) On-time supply

five) Aggressive cost and good services

6) Good customer opinions from domestic and global marketplace

seven) International sophisticated-stage gear this kind of as CNC, numerical lathes, furnance, welding

equipment, CMM and detect &screening gear we used to ensure our product’s quality.

8) EPT service, your need is our pursued.

nine) ISO9001:2008 and TS16949 quality management

10) Standard: ASTM BS DIN and many others

FAQ

1. What are the main materials of your products?

We are focused on casting and processing of grey iron and ductile iron products.

2. What is your MOQ?

We will arrange production based on your drawings and deliver your products as per your requirements. We will do our best to meet your demands.

3. What is your main equipment?

Our casting equipment is brought from Japan. They mainly include: FBO auto molding lines, sand lines, cleaning lines, vertical and horizontal machining centers and CNC machining center.

four. Do you make the molds by yourself?

We are facilitated with advanced mold making equipment and CNC processing machining center. Therefore, we can make molds independently.

five. What are your advantages?

one) Professional staff

2) 24 years of casting experience

3) Rigorous quality control system

4) On-time delivery rate is over 98%

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 diverse branches. For more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) component quantities or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our firm and the outlined substitute parts contained herein are not sponsored, authorized, or made by the OEM.

China manufacturer & factory supplier for China in Cordoba Argentina manufacturer Smooth Transmission Low Noise AT5 Timing Pulley With high quality best price & service

First of all: revolutionary item engineering. We are continually strengthening properly-established and set up goods in the locations of travel and conveyance technological innovation or are hunting for possible innovations. One particular case in point for this is the servicing-cost-free chain. Next: superb creation engineering. Our production processes are also constantly improved upon. Very regularly effective, new items are only achievable since of progressive generation methods. Thirdly: proficient software consulting.Ever-Electricity Team CO., LTD. IS Expert IN Creating ALL Varieties OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Vehicle GEARBOXES, PTO Drive SHAFTS, Specific REDUCER & Connected Equipment Components AND OTHER Connected Products, SPROCKETS, HYDRAULIC Method, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Speed VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Fast Particulars

- Applicable Iwhile the varieties of yokes for the relationship of the PTO shafts with the agricultural employ includes the exact same earlier mentioned splined yokes and also yokes with recessed button and/or ball collar with:ndustries:

-

Building Content Outlets, Production Plant, Equipment Restore Outlets, Meals & Beverage Manufacturing facility, Farms, Strength & Mining

- Product title:

-

Timing pully

- Application:

-

Electricity Transmission

- Coloration:

-

Silver,natura,black

- Bore Variety:

-

Taper bore, Straight bore

- Bundle:

-

Carton

- Approach:

-

Hobbing

- MOQ:

-

10pcs

- Teeth:

-

18-60

- Normal:

-

Common

Source Capability

- Supply Ability:

- 5000 Piece/Parts per Thirty day period

Packaging & Supply

- Packaging Particulars

- carton box, picket case

- Port

- Tianjin/shanghai/ningbo

EPG is prepared to cooperate sincerely and create generally with buddies!

-

Lead Time

: -

Quantity(Baggage) one – 100 101 – three hundred >300 Est. Time(days) ten 15 To be negotiated

On-line Customization

EPG provide widest variety of gearbox and velocity reducers, conveyor chains and transmission elements like gear, sprocket, racks, pulley, shaves and taper bushes and so on for numerous programs

Merchandise Description

|

Item identify |

Timing belt pully |

||||

|

Substance |

Aluminum Alloy, Copper, Stainless Metal, Metal, Carbon Steel, G25, G3000 |

||||

|

Machinining Process |

Brass Forging and Machining, Precision Machining and Large Machining, |

||||

|

Finishing |

Anodized, Black Oxide, Galvanized, Phospharing |

||||

|

Packing |

Normal export circumstance(Particulars according to customer’s need) |

||||

|

Tooth kind |

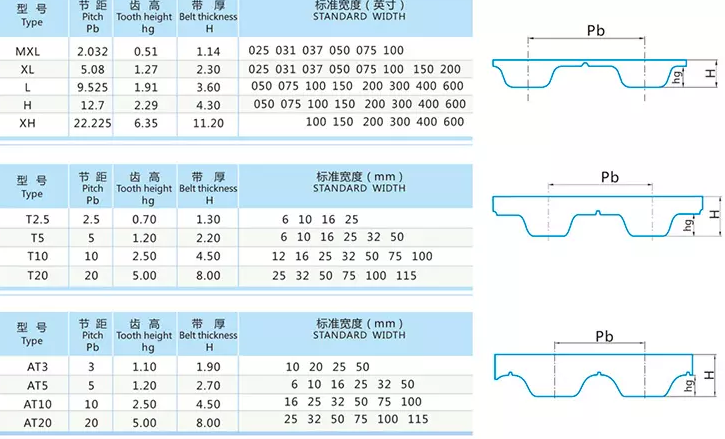

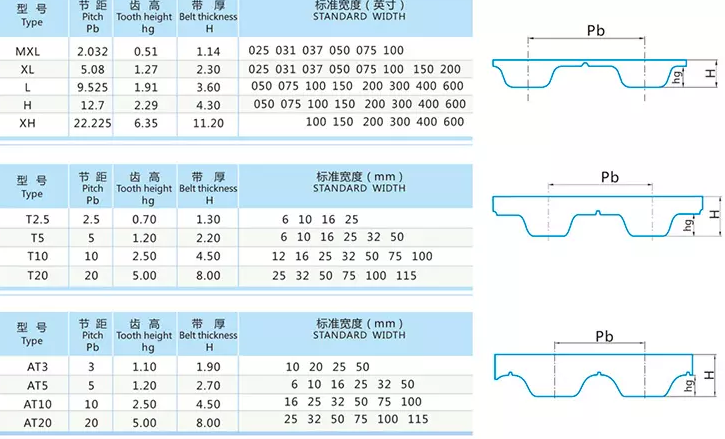

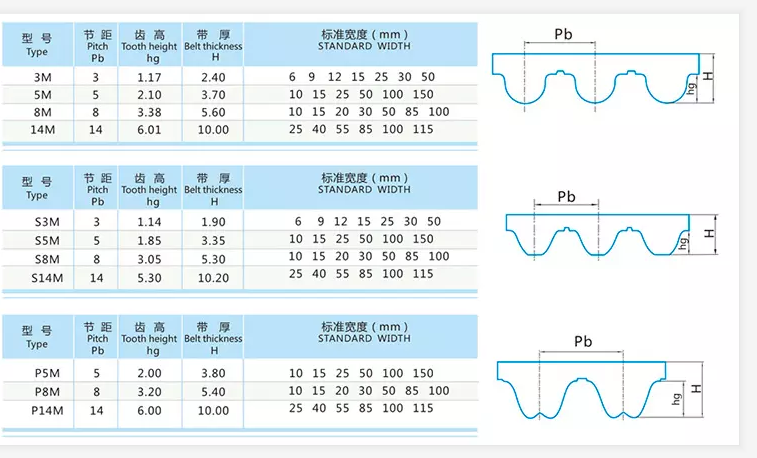

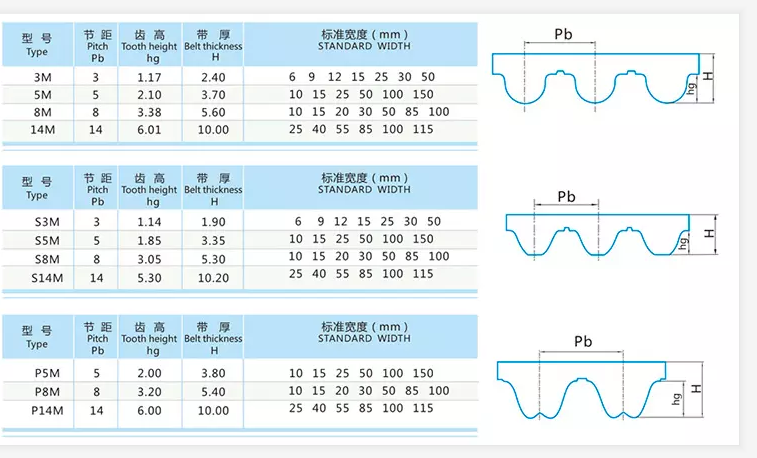

T variety:MXL, XL, L, H, XH, XXH,T2.5, T5, T10, T20, AT5,AT10,AOur toughness lies in adaptable manufacturing processes this kind of as turning/milling, challenging-turning, cylindrical grinding, gear chopping, erosion, making grinding, and profile grinding, which we complete to the optimum good quality specifications. A additional main competency is our in-residence warmth remedy facility, the place gearing components are annealed, case-hardened and cryogenically dealt with. Each and every hardened batch is tested with regard to floor hardness, scenario depth, and, the place acceptable, microstructure problem at our in-house materials screening lab. Even very complicated form and placement tolerances as properly as gearing traits can be ensured at our group 3 screening room utilizing Zeiss and Klingelnberg measuring equipment.T20 |

||||

|

AT Series |

ARC type:2M, 3M, 5M, 8M, 14M, 20M,S2M, S3M, S5M, S8M, S14M |

||||

|

Timing pully kind |

AS sort,AF variety,BS sort, BF kind,WF variety A=Timing pulley with no hub |

||||

|

Bore Variety |

Taper bushed bore,pilot bore |

||||

Catalog

Software

Our Organization

HangZhou EPG – The largest transmission elements manufacuturer in China Electrical Equipment Co.,Ltd was launched in HangZhou in 2008 and is a skilled maker and exporter that is concerned with the design and style, improvement and manufacturing.With thorough requirments, we can also develop your unique made product. Our product selection consists of all sorts of helical equipment, spur gear, bevel equipment, equipment rack, worm gear, sprockets,chains, bearings.Maintaining in head that excellent support is the essential to cooperating with customers, we attempt to fulfill high good quality specifications, provide aggressive rates and guarantee prompt supply. In this way, our goods have continued to achieve market place acceptance and clients satisfaction above the past couple of a long time. We are aiming to satisfy the calls for of the clientele all around the entire world..If you are interested in any of our goods or would like to go over a likely order, make sure you feel free to speak to us. We are hunting ahead to building profitable company interactions with new consumers around the planet in the potential.

· Our Principle: “Reliability Supremacy, and Buyer Very first”

· Our Promise: “High high quality goods, and Outstanding Provider”

· Our Worth: “Currently being Honesty, Doing the Ideal, and Lengthy-lasting Growth”

· Our Purpose: “Build to be a leader in the electricity transmission areas market in the planet”

EPG – The largest transmission elements manufacuturer in China Principal Items

Industrial Sprocket

Motorcycle Sprocket

Roller Chain

Spur Gear

Helical Gear

Bevel Gear

Plastic/POM/Nylon Equipment

Small Pinion Equipment

Worm Equipment and shaft

Gear Rack

Timing Pulley

Taper Bushing

Chain Guides

Linear Rail and Block

Ball Screw

Packing & Shipping and delivery

1.EPG – The largest transmission parts manufacuturer in China PACKING

two.Cargo

Manufacturer Cost made in China – replacement parts – in Jodhpur India of Sheaves Wire Rope Pulley Block with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 diverse branches. For a lot more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Sheaves wire rope pulley block is the essential as well EPT for hoisting&period Sheaves wire rope pulley block has easy structure and effortless to use&period of time Sheaves wire rope pulley block can adjust direction of pulley&comma metal wire rope and substantial fat cargoes&comma especially collection of pulley merged with windlass&comma ma EPT and EPT lifting machinery&time period It widely used in installation and development&time period Its merchandise from &period03T to 320T&comma and whee EPT not exceed 10&interval Our lifting too EPT such as hooks&comma chain lifting and handing beam&comma you can choose a single according to your want&interval

Specs

Made of substantial top quality casting steel and carbon steel&comma closed sort&comma easy handling

1&time period Crane pulley block with eight sheave&comma shackle head

two&time period Substance&colon

Sheave&colon Casting metal

Shackle&colon forty five&num carbon steel

Plate&colon 235&num carbon steel

three&period of time Doing work load limite&colon Up to a hundred and sixty ton

4&period Suitable wire rope&colon Count on diffrent sorts

5&period Excess weight&colon From 1kg to 300kg

six&time period Packing&colon Nylon or gunny cloth

Complex Prameters

| Sort | SHEAVE | S&periodW&periodL | DIMENTIONS&lparMM&rpar | N&periodW | WIRE ROPE | |

| DIA&lparMM&rpar | &lparT&rpar | Length | Wideth | &lparKG&rpar | DIA&lparMM&rpar | |

| YB75X1 | 75 | &period5 | 178 | 85 | 1&period1 | 8 |

| YB100X1 | one hundred | 1 | 235 | 121 | 1&period8 | 8 |

| YB125X1 | one hundred twenty five | 1&period5 | 305 | a hundred forty five | 3&period5 | nine |

| YB150X1 | one hundred fifty | 2 | 350 | a hundred and eighty | five&period1 | 12 |

| YB200X1 | 200 | four | 425 | 225 | eleven&period5 | sixteen |

| YB250X1 | 250 | 5 | 495 | 275 | 17 | 22 |

| YB75X2 | 75 | &period5 | 178 | eighty five | 1&period8 | eight |

| YB100X2 | a hundred | one | 235 | 121 | two&period8 | 8 |

| YB125X2 | 125 | 1&period5 | 305 | 145 | 5&period5 | 9 |

| YB150X2 | one hundred fifty | 2 | 350 | one hundred eighty | 8&period5 | 12 |

| YB200X2 | 200 | 4 | 425 | 225 | 16&period5 | 16 |

| YB250X2 | 250 | 5 | 495 | 275 | twenty five&period5 | 22 |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 various branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of unique products manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the detailed substitute areas contained herein are not sponsored, accepted, or produced by the OEM.

Timing shop made in China – replacement parts – in Douala Cameroon Belt Tensioner Pulley for Land Rover Discovery I 89-98 Lhp10016 Lhp10011 with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 different branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| Product Name | belt tensioner pulley for Land Rover DISCOVERY I 89-ninety eight |

| OEM Number | LHP10016 LHP10011 |

| Diameter | 60mm |

| Peak | 32mm |

| Bodyweight | .46kg |

| MOQ | 100pcs |

| Guarantee | 12 months |

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 distinct branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original gear manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our company and the detailed substitution elements contained herein are not sponsored, accepted, or manufactured by the OEM.

Plastic factory made in China – replacement parts – in Chihuahua Mexico Pulley Wheels, Nylon Belt Tensioner Pulley, Small Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For far more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Plastic pulley wheels,nylon belt tensioner pulley,tiny pulley

EPT (ZheJiang ) EPT Products CO.,L EPT specializing in customized products, Plastic pulley wheels,nylon belt tensioner pulley,modest pulley can be manufactured based mostly on consumers style.

Merchandise Positive aspects:

one. Customer’s design and style and symbol

two. Little buy acceptable

3. Free samples

4. a hundred% raw material

5. Variety of substance

6. Higher precision & high quality handle

seven. Aggressive rates

eight. Risk-free packing & prompt shipping

Product Specification:

| Product | Plastic pulley wheels,nylon belt tensioner pulley,tiny pulley |

| Material | nylon ,mc nylon, POM,Abdominal muscles,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Colour | Black, white, crimson, green or according to Pantone code |

| Free of charge samples | one-5 pcs |

| MOQ | 1pc |

| Size | As per customer’s request |

| Processing Technic | CNC machining, injection molding & extrusion |

| Hardness | Shore A |

| Working temperature | -sixty~350ºC |

| Tolerance | ±0.05mm |

| Density | .9-2.5g/cm³ |

| Service | OEM or ODM |

| Production basis | Samples or drawings |

| Certification | ROHS,Fda,ISO9001:2000 |

| Conductivity | Conductive or insulative |

| Working life | one-30 years |

| Software | 1.transmission system in areas of industrial equipment 2.medical device, automotive, office equipment, household three.appliances,digital electronic, toy etc. |

Lead Time:

Rubber products: 3-7 times soon after payment

Plastic items: 5-7 times after payment

CNC machined parts: 3-ten times soon after payment

Company Information:

EPT (ZheJiang ) EPT Equipment CO.L EPT is a professional manufacture for EPT mechanical parts in rubber & plastic & metal substance. We have our very own laboratory, mould perform shop, CNC workshop, injection workshop, compression workshop, printing and electro-plating workshop.

| Rubber & Plastic workshop | Our operate shop have possess advance making line for rubber & plastic goods, which will make positive for quality and lead time. |

| Mould workshop | We have our personal workshop to make sure mold precision and lead time. |

| CNC workshop | We introduced DMG (Deckel Maho Gildemeister) from Germany for precision and production ability. |

Packaging & Shipping:

All the goods will be packed nicely prior to shipping and delivery. They will be delivered by sea,by air or by express according to the weight, the volume, or the customer’s prerequisite

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) element figures or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our business and the shown substitution parts contained herein are not sponsored, authorized, or created by the OEM.

Great best made in China – replacement parts – in Basel Switzerland Quality Hot Sale Customized Diamonds Rubber Lagging Conveyor Pulley Made in China with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| Type | Belt width(mm) | Standard Diameter(mm) | Length(mm) |

| Drive Pulley | 500 | 500 |

Length of the pulley depends on the belt width of the conveyor |

| 650 | 500~630 | ||

| 800 | 630~1000 | ||

| 1000 | 800~1150 | ||

| 1200 | 800~1150 | ||

| 1400 | 1000~1350 | ||

| 1600 | 1150~1600 | ||

| 1800 | 1150~1800 | ||

| 2000 | 1350~2000 | ||

| 2200 | 1600~2200 | ||

| 2400 | 1800~2400 | ||

| Bend Pully | 500 | 250~500 | |

| 650 | 250~630 | ||

| 800 | 250~1000 | ||

| 1000 | 250~1600 | ||

| 1200 | 250~1600 | ||

| 1400 | 315~1600 | ||

| 1600 | 400~1600 | ||

| 1800 | 400~1600 | ||

| 2000 | 500~1600 | ||

| 2200 | 630~1600 | ||

| 2400 | 800~1600 |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Xh400 made in China – replacement parts – in Tomsk Russian Federation Steel Cast Iron Timing Pulley with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For much more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Overview

———————————————————————————————————————————————————————————————————————————————–

Timing Pulley Numbers:XL, L, H, XH & 3M, 5M, 8M, 14M, 20M

Regular Timing Pulleys Introduction:

&Substance:ASTM G-3000 or or C1045 metal,For every batch of casting,inspection certificate such as chemcial composition, tensile strength, hardness and many others will be tested & issued for each and every batch steel materials, subsupplier will supply content certification issued by metal plant.

&Machining:Precesion machining for pulley with inventory bore, taper bore .

&Addition:With Flang, and Keystocks when Required.

&End: Black oxide for metal Timing Pulleys,black phosphate for ca EPT iron Timing Pulleys.

&Deal: Cartons with sealed plastic bag.

Timing Pulleys:Created to Orders’ Prints and/or Samples

EPT Timing Pulleys Introduction:

&Content:Aluminium,Alloy content and many others.

&Complete:No surface remedy,oiled.

&Bundle: Cartons with sealed plastic bag.

———————————————————————————————————————————————————————————————————————————————–

EPT Capacity

EPT Capacity: 20000 Piece/Items for every Thirty day period

Added Support: OEM is welcome

QC Method: ISO9001:2008

———————————————————————————————————————————————————————————————————————————————–

Packaging & Shipping and delivery

Package deal: Picket box/Paper carton

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

About EPT considering that 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in system area and punching/stamp

ing field since 1984. Our primary solution, NMRV worm equipment speed reducer and sequence helical gearbox, XDR,

XDF, XDK, XDShave achieved the sophisticated technique index of the congeneric European and Janpanese produc

ts, We supply standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders

of non-standard items, this kind of as gears, shafts, punching components ect, in accordance to customers’ Drawings or sam-

ples.

Our business has total established of equipment such as CNC, lathes, milling machines, gear hobbing equipment, g-

ear grinding machine, equipment honing machine, equipment shaping equipment, worm grinder, grinding equipment, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing equipment and s-

o on. We have superior tests equipments also.

Our business has proven favorable cooperation associations with sub-suppliers involving casting, uncooked mat-

erial, heat therapy, surface finishing and so on.

The use of first tools manufacturer’s (OEM) component quantities or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our company and the shown substitution components contained herein are not sponsored, approved, or made by the OEM.