Product Description

Product Description

358286A1 universal joint drive shaft New Planetary Drive Shaft Fits Case-IH Backhoe Models 580L Series 2

| Part NO: | 358286A1 |

| Used for: | Fits Models: (580L- Ser. II), 580M, 570MXT, 585G, 586G, 588G Part # 358286A1 Description: Fits Models At A Glance Fits Cases Backhoes: (580L II – After Serial # JJG5715A1, 138940, 358286A1 |

| Related Product: | Starter/Alternator/Solenoid Valve/Overhaul Kit/Turbo Repair Kit |

| Feature: | Good quality;Fast delivery;6Months Warranty |

Certifications

HangZhou CZPT Mechanical & Electrical Co., Ltd. is a leading provider of high-quality replacement parts for various industries. With a strong focus on customer satisfaction for over 15 years, we have established ourselves as a market leader in the following product categories:

View More Products, You Can Click Product Keywords…

| Main Products | |

| Diesel Engine Parts | Construction Equipment Parts |

| Agriculture Equipment Parts | Aerial Work Platform Parts |

| Generator Parts | |

Our comprehensive product categories include Engine parts, Electrical Parts, Hydraulic parts, Transmission parts, Classis Parts, and more. As a unique supplier, we prioritize our customers as our most valuable resource. We are dedicated to providing exceptional service and competitive prices.

OUR TEAM & EXHIBITION

Packaging & Shipping

FAQ

Q:Are you trading company or manufacturer?

A:We are trading company,but have own outsourcing factories, production quality is guaranteed.

Q:Why choose FridayParts?

A:

15+ Years Experience

176+ Countries Sold

20000+ Inventory

60000 SQ FT Warehouse

1000+ New ProductsYearly

Q: How long is your delivery time?

A: Generally it is 1-2 days if the goods are in stock. or it is 7-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for quality testing but not free.

Q: How about the warranty?

A: Usually Our Warranty is 12 month. Otherwise, if any quality problem, we accept money refund in 15 days..

You can try Trade Assurance, you’ll enjoy:

— 100% product quality protection

— 100% on-time shipment protection

— 100% payment protection for your covered amount

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CCC, COP, ISO9001, CE, E-Mark, RoHS, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Universal Joint Drive Shaft |

| Material: | Universal Joint Drive Shaft |

| Type: | Universal Joint Drive Shaft |

| Transport Package: | Neutral |

| Customization: |

Available

| Customized Request |

|---|

How do drive shafts ensure efficient power transfer while maintaining balance?

Drive shafts employ various mechanisms to ensure efficient power transfer while maintaining balance. Efficient power transfer refers to the ability of the drive shaft to transmit rotational power from the source (such as an engine) to the driven components (such as wheels or machinery) with minimal energy loss. Balancing, on the other hand, involves minimizing vibrations and eliminating any uneven distribution of mass that can cause disturbances during operation. Here’s an explanation of how drive shafts achieve both efficient power transfer and balance:

1. Material Selection:

The material selection for drive shafts is crucial for maintaining balance and ensuring efficient power transfer. Drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, stiffness, and durability. These materials have excellent dimensional stability and can withstand the torque loads encountered during operation. By using high-quality materials, drive shafts can minimize deformation, flexing, and imbalances that could compromise power transmission and generate vibrations.

2. Design Considerations:

The design of the drive shaft plays a significant role in both power transfer efficiency and balance. Drive shafts are engineered to have appropriate dimensions, including diameter and wall thickness, to handle the anticipated torque loads without excessive deflection or vibration. The design also considers factors such as the length of the drive shaft, the number and type of joints (such as universal joints or constant velocity joints), and the use of balancing weights. By carefully designing the drive shaft, manufacturers can achieve optimal power transfer efficiency while minimizing the potential for imbalance-induced vibrations.

3. Balancing Techniques:

Balance is crucial for drive shafts as any imbalance can cause vibrations, noise, and accelerated wear. To maintain balance, drive shafts undergo various balancing techniques during the manufacturing process. Static and dynamic balancing methods are employed to ensure that the mass distribution along the drive shaft is uniform. Static balancing involves adding counterweights at specific locations to offset any weight imbalances. Dynamic balancing is performed by spinning the drive shaft at high speeds and measuring any vibrations. If imbalances are detected, additional adjustments are made to achieve a balanced state. These balancing techniques help minimize vibrations and ensure smooth operation of the drive shaft.

4. Universal Joints and Constant Velocity Joints:

Drive shafts often incorporate universal joints (U-joints) or constant velocity (CV) joints to accommodate misalignment and maintain balance during operation. U-joints are flexible joints that allow for angular movement between shafts. They are typically used in applications where the drive shaft operates at varying angles. CV joints, on the other hand, are designed to maintain a constant velocity of rotation and are commonly used in front-wheel-drive vehicles. By incorporating these joints, drive shafts can compensate for misalignment, reduce stress on the shaft, and minimize vibrations that can negatively impact power transfer efficiency and balance.

5. Maintenance and Inspection:

Regular maintenance and inspection of drive shafts are essential for ensuring efficient power transfer and balance. Periodic checks for wear, damage, or misalignment can help identify any issues that may affect the drive shaft’s performance. Lubrication of the joints and proper tightening of fasteners are also critical for maintaining optimal operation. By adhering to recommended maintenance procedures, any imbalances or inefficiencies can be addressed promptly, ensuring continued efficient power transfer and balance.

In summary, drive shafts ensure efficient power transfer while maintaining balance through careful material selection, thoughtful design considerations, balancing techniques, and the incorporation of flexible joints. By optimizing these factors, drive shafts can transmit rotational power smoothly and reliably, minimizing energy losses and vibrations that can impact performance and longevity.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2024-04-25

in Dakar Senegal sales price shop near me near me shop factory supplier Fairfield Planetary Gearbox 7HP 11HP for Scissor Lifts Drive Hub manufacturer best Cost Custom Cheap wholesaler

Additionally, all our production methods are in compliance with ISO9002 expectations. Our products are applied in several fields. Our organization pays distinct interest to customers’ wants, listening to the specific specifications of every buyer and guaranteeing complete fulfillment.

Fairfield planetary EPT 7HP 11HP For Scissor lifts EPT hub 7HPF01FZZ3B048

Concrete Mixer P3301 P4300 P5300 Planetary EPT

The EPT for concrete mixer EPTs is used in the EPT program of concrete mixer EPTs.

The EPT adopts planetary EPT EPT, which has the attributes of secure torque driving, compact structure, considerably less routine maintenance and EPT services daily life. The reduction EPT physique can be bolted to the mounting bracket of the frame or straight linked to the frame and related to the drum through the output flange. The output flange enables for a specified angle of oscillation in all directions to meet the needs of numerous complicated situations. This EPT functions as a front help for the drum and EPTs the drum to rotate by means of the output flange.

We could supply the EPT EPT pump and motor, also the inner spare areas as below product:

1 A8VO: A8VO55,A8VO80,A8VO107,A8VO160

two,A2FO: A2FO5 A2FO10 A2F12 A2FO16 A2FO23,A2FO28,A2FO32,A2FO45,A2FO56,A2FO63 A2FO80

three,A4VSO: A4VSO40,A4VSO45,A4VSO56,A4VSO71,A4VSO125,A4VSO180,A4VSO250,A4VSO500,

four,A4VG: A4VG28,A4VG45,A4VG50,A4VG56,A4VG71,A4VG125,A4VG180,A4VG250

5,A6V: A6V55,A6V80,A6V107,A6V160,A6V225,A6V250

six,A7V: A7V16,A7V28,A7V55,A7V80,A7V107,A7V160,A7V200,A7V250

7,A8V: A8V55,A8V80,A8V107,A8V115,A8V172

eight,A10VSO: A10VSO10,A10VSO18 A10VSO28,A10VSO43,A10VSO45,A10VSO71,A10VSO100,A10VSO140

nine,A10VD: A10VD17,A10VD21,A10VD28,A10VD43,A10VD71

ten,A11V: A11V50 A11V90 A11V130,A11V145 A11V160,A11V190,A11V250

11,PVV,PV7: PV2.PVV4.PVV5.PVV21.PVV41.PVV42.PVV51.PVV52.PVV54,PV7-1X,PV7-2X

12,PGF,PGH,PGP: GF1-2X,PGF2-2X,PGF3-3X,PGH2-2X,PGH3-2X,PGH4-2X,PGH5-2X,PGP2-2X,PGP3-3X

thirteen Other folks: AP2D21,AP2D25,AP2D36,AP2D38

7HPF01FZZ3B048

–Volvo 8820,7820,6620,ABG423,ABG325,ABG525

–VOEPT, S1800, S1800-1,S1800-two,S2100, S2100-one.S2100-2, S2500.

–DYNAPAC, F141CS, F181CS,

—DEMAG:135CS, DG141CS, DF145CS

—WTU75, RP75, wtu95, WTU125, RP125, LTU125

—EPT: LTU90, LTU120

—EPT: LTU90, LTU120

1, excellent top quality

2, low price, EPT EPT motor EPT

three, deliver quickly

Our firm can make EPT EPT in accordance to customer’ requirement.

HYDROTRAC GFT is an excellent driving ingredient for wheel or keep track of driving cars, and other relocating tools and commonly used in excavator, EPTing EPT, drill EPT, cell crusher, engineering EPTry, mining, tunnel EPTry, agricultural EPTry, and so forth. In the meantime, diverse motor connectors and proportions are offered on ask for. It is an perfect substitute of EPT products.

Best China manufacturer & factory high in Caracas Venezuela precision Drive Planetary Crown Wheel And Pinion Toy Right Angle Bevel Gear With high quality best price

The new goods contain a series of higher-tech and large high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, substantial-velocity tooth chains, timing chains, self-lubrication chains, among which have variety substantial speed tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China.

In our sales system we offer you normal and wide-angle PTO travel shafts. Relating to the customers’ requirements there are various dimensions, lengths and basic safety aspects (clutches) accessible.

Overview

Quick Details

- Relevant Industries:

-

Manufacturing Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

.4-20

- Service:

-

Reply in 12 hours at any time

- Standard material:

-

20CrMnTi

-

In buy to find a appropriate gearbox for your software from the basic phase, our on-line SIZING ASSISTANT style instrument is best: dependent on your application info or the preferred motor, a ideal gearbox can be picked from our portfolio and geometry adjustment done in a few seconds. Upon demand, we can also send out you a ask for for quotation straight on-line.

- Material2:

-

Steel, Stainless metal, POM and many others.

- Warmth treatment method:

-

Tooth hardened HRC55-sixty three

Source Capacity

- Source Capability:

- 5000 Piece/Pieces for each Month

Packaging & Shipping

- Packaging Details

- Antirust oil + Paper bag + Wood case

- Port

- Ningbo, Shanghai or as request

-

Direct Time

: -

Quantity(Baggage) 1 – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(days) thirty 40 60 To be negotiated

Online Customization

high precision Push Planetary Crown Wheel And Pinion Toy Proper Angle Bevel Equipment

Spiral bevel gears

Our spiral bevel gears are welcomed by several buyers for its steady substantial quality and competitive cost.

The producing character of JH spiral bevel gears:

1. Gear size: the greatest diameter is 1800mm

two. Material: Most typical metal is higher power steel 20CrMnTi. Others can be steel C45, stainless steel, substantial strength metal, copper, aluminium, plastic, POM and so forth

3. Spiral bevel Gear module: .3-twenty (pitch from .942-62.80mm, DP 1.27-85)

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so on.

5. Quality: steady and high, grade 7 for without tooth grinding, grade 6 soon after enamel grinding, quality 5 for exact grinding.

Costs for over high quality are very aggressive for us.

6. Heat remedy: teeth can be hardened to HRC fifty five-63.

The good quality character of JH spiral bevel gears:

1. Stable transmission and lower sounds

2. Effectively avoid typical tolerance dependent on high precision

3. The enamel can be floor to grade 6 and quality 5 top quality

four. The bore will be polished to smooth and large precision

5. The price is competitive even the good quality is higher.

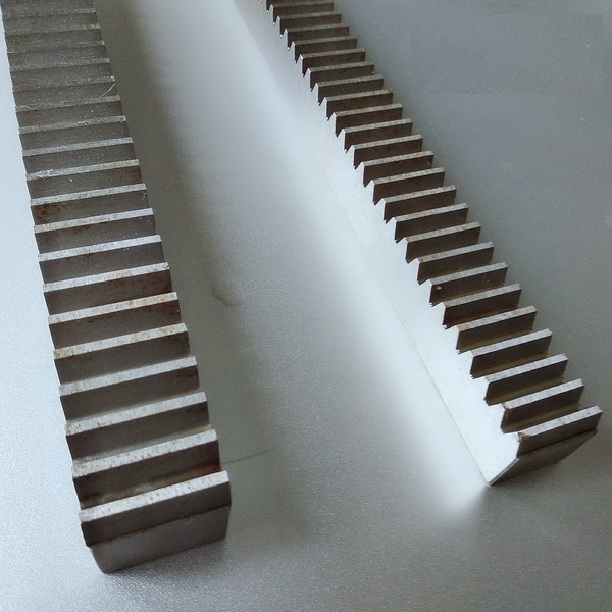

| Facilities |

Machining centre, Gleason machines, CNC equipment hobbing machine, CNC equipment shaper, CNC equipment grinding device, CNC turning machine, CNC milling machine, Y58200 CNC big equipment rack shaper, Y58125A equipment rack shaper, England gear rack shaper, and Russia equipment rack shaper, |

| Equipment varieties |

Helical gears (a lot more and more widely used for its secure transimission) Spur gears Hub gears Bevel gears Bevel spiral gears Equipment ring and so forth. |

| Substance |

Metal: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and so forth. Aluminium alloy: 6061, 5083, 7050, etc. A lot more: PA6, PA66, POM, Abdominal muscles and many others. |

| Area | Polishing Plating Galvanized Blacken chromium plating, nickel plating painting and so on. |

Complete expertise on Spiral bevel gears

Our Providers

one. Shipping time: 15-25 days for small purchase

30-45 times for large get. (By no means delayed till now)

Can be mentioned for more urgent buy.

2. Response time: usually in 1 hour and in twelve hours even in our vacations.

three. Procedure feedback: Photos or vedios will be sent for 2-3 instances to inform you the creating situation.

four. Examination report: The take a look at report can be supplied as request.

5. Payment conditions: T/T, L/C, D/P, D/A, O/A, M/T, D/D and many others.

6. Trade phrases: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Info

FAQ

Q: Company?

A: Indeed. Because 2004 only emphasis on generating high high quality gears and racks.

Q: Reaction time?

A: Reply quite before long, and reply in 12 hrs at any time.

Our technicians are often jointly with salesmen, so your any questions can be replied really shortly.

Q: Price?

A: Drawings are a lot more appriated for quotation. Or, make sure you tell us your request, we will make drawings for your examine.

Q: Delivery time?

A: 15-25 days for modest order (<200 pcs), 30-45 days for large order.

Orders in no way be delayed, the items will be despatched on time as arrangement.

Q: Top quality?

A: Middle and higher high quality is more aggressive.

Q: Payment conditions?

A: T/T for significantly less than US$twenty,000 order, and L/C, D/P, D/A, O/A, M/T, D/D and so on. for massive orders.

Q: Trade conditions?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Our company has strong financial strength, builds up a technician staff contingent with large quality, possesses the generation assembly line of technicalization in China and excellent system checking on solution top quality and runs marketing and advertising networks throughout the place.

Scorching related merchandise

Contact us

Best China manufacturer & factory T Series 90 degree 2: 1 ratio right angle gearbox planetary reduction steering gear box power transmission drive With high quality best price

PersonnelOur sales persons are well trained to accommodate your requests and speak English for your convenience.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

Up to 3378Nm

- Input Speed:

-

750-1500rpm

- Output Speed:

-

3~1450r/min

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Our company is located in XiHu HangZhou Zhejiang Province. T Bearing:

-

C&U

- gear precision grade:

-

din 4

Supply Ability

- Supply Ability:

- 1000 Unit/Units per Month

Packaging & Delivery

-

Standard products and individualized solutions for an optimal drive

- Packaging Details

- Standard wooden case

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

- Port

- Ningbo Port, Shanghai Port

Online Customization

T Series 90 degree 2: 1 ratio right angle gearbox planetary reduction steering gear box power transmission drive

Product Description

-Self-locking ability

-Can be driven directly by motor or other power or manual

-Can be customized according user’s demand

-Compact configuration, small size, lightweight

-Convenient installation, flexible operation

-High reliability and stability

-Long service life

-More connection form etc.

Screw jak is applied to all fields for lifting or pulling, such as Aircraft maintenance platform, Solar plate, machinery, metallurgy, water conservancy, medical treatment, chemical industry, culture and hygienist etc.

|

Product Name |

T series Spiral Bevel Gearbox |

|

model no. |

T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

|

Ratio |

1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1 |

|

gear Material |

high grade synthetic diamond 50CrMnT |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines, Precision grade : DIN 4 |

|

spindle |

high purity steel alloy 40Cr piece |

|

Noise Test |

Bellow 65dB |

|

Warranty |

1 year |

Company Information

Certifications

Our Services

Expo& Customers

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

PLanetary China gearbox for TRC series coaxial helical drive power transmission gearbox speed reducer – Supplier Manufacturer wholesaler Factory

For much more data.: Cell/Whatpp: +8613083988828

In 2000, EPG took the lead in gaining ISO14001 setting management certification and thereafter passed the inspection of clean manufacturing and recycling economic climate, successful the title of “Zhejiang Inexperienced Enterprise”.Our organization has solid economic energy, builds up a technician group contingent with substantial top quality, possesses the generation assembly line of technicalization in China and best system examining on item high quality and runs marketing and advertising networks during the nation.

Overview

Swift Specifics

- Applicable Industries:

-

Lodges, Garment Retailers, Developing Material Outlets, Manufacturing Plant, Machinery Restore Retailers, Foods & Beverage Manufacturing unit, farms, Energy & Mining, Building functions

- Spot of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

three.5~500N.m

- Input Pace:

-

1450/960rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

three.77~fifty.four

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C&U,LYC, HRB,ZWZ,SKF,NSK

Supply Potential

- Supply Capability:

- five hundred Device/Units per Month

Packaging & Shipping

- Packaging Particulars

- Wood boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

On the internet Customization

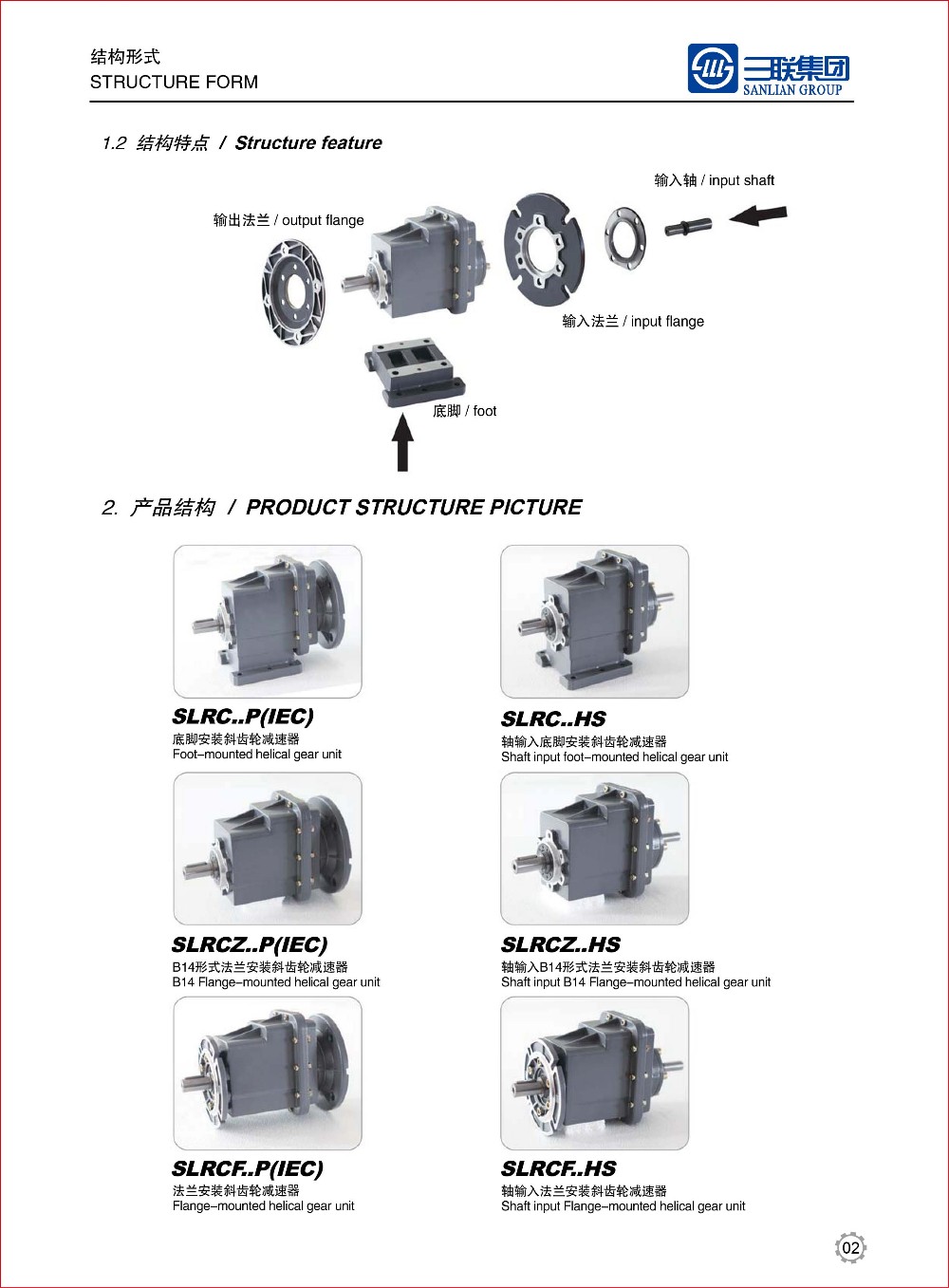

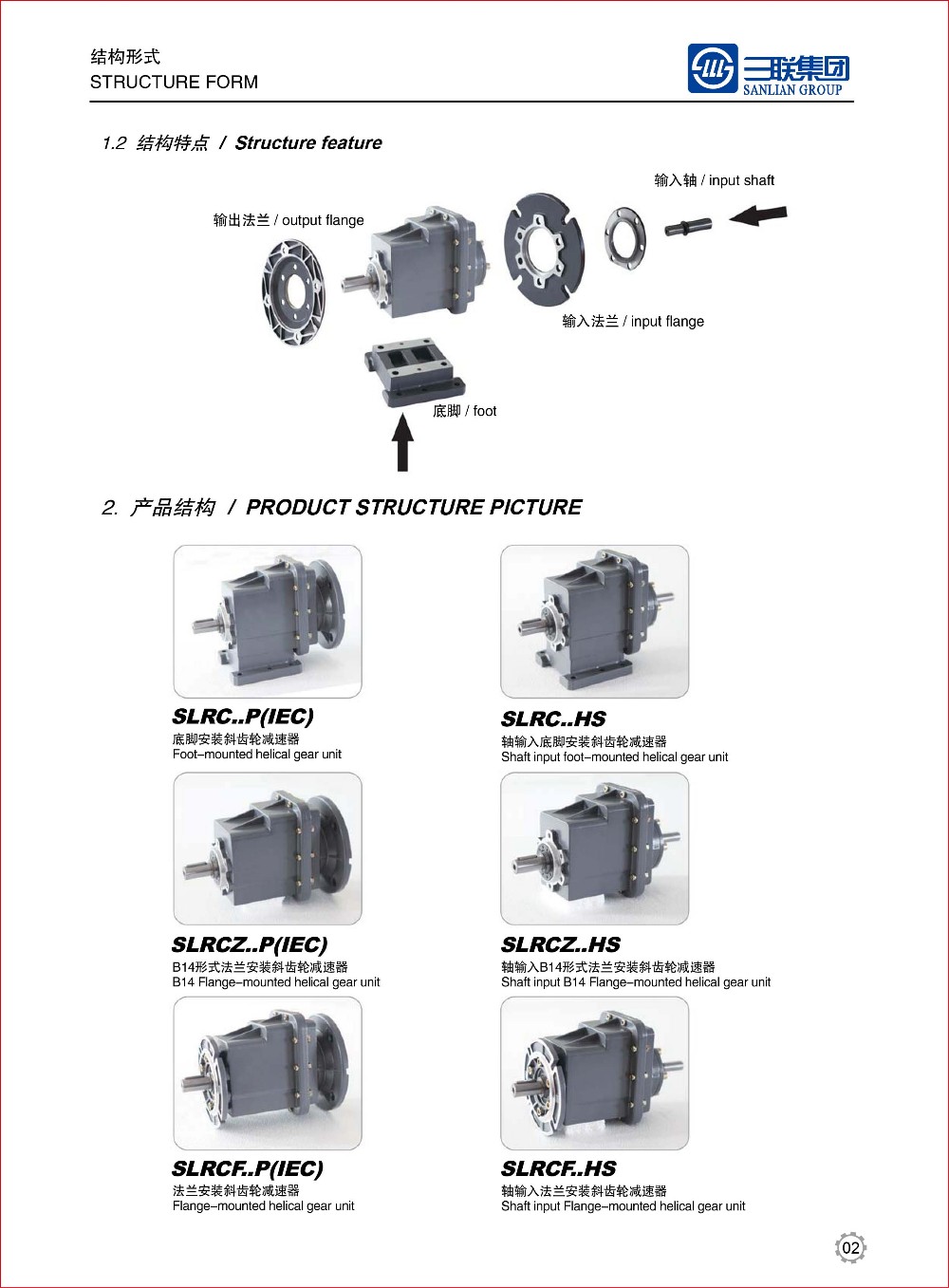

PLanetary gearbox for TRC collection coaxial helical push power transmission gearbox pace gearbox

Product Description

TRC series aluminium housing helical velocity gearbox gear gearbox

The very modular is a style features of SRC helical gearboxes range. It can be connected respectively with motors these kinds of as regular motor,brake motor,explosion-evidence motor,frequency conversion motor,servo motor,IEC motor and so on. This variety of item is commonly employed in travel fields this sort of as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to established up the variation essential utilizing flanges or feet.

Item functions:

SLRC sequence helical gear models has a lot more than four varieties,power .12kw-4kw,ratio3.sixty six-54max torque120-500NM,It can be linked(foot or flange)discretionary and use multi-mounting positions in accordance customers’ requirements

one Ground-hardened helical gears

two. Modularity, can be mixed in several types

3. Aluminum casing, mild weight

4. Gears in carbonize challenging,resilient

5. Universal mounting

6. Refined design, compact in construction and minimal sound

| Certification | ISO9001-2008 |

| Bearing | C&U |

| Color | Blue/black |

| Ratio | three.77~fifty.four |

| Mount Position | Foot Mounted |

| Bearing | LYC, HRB,ZWZ,SKF,NSK |

Company Information

Certifications

Our Solutions

Packaging & Delivery

Expo& Consumers

Related Merchandise

FAQ

: Are you investing organization or company ?

A: We are factory.

Q: How prolonged is your shipping time?

A: Generally it is five-ten days if the goods are in stock. or it is 15-20 days if the products are not in stock, it is according to amount.

Q: Do you give samples ? is it cost-free or further ?

A: Indeed, we could offer you the sample for free of charge cost but do not shell out the cost of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in progress ,balance just before shippment.

If you have one more query, pls feel free of charge to speak to us as beneath:

EPG – one particular of the biggest transmission manufacturing facility in China, major items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare areas and agricultural components manunfacuter in ChinaFor much more info.: Cell/Whatpp: +8613083988828