Product Description

Company Profile

Workshop

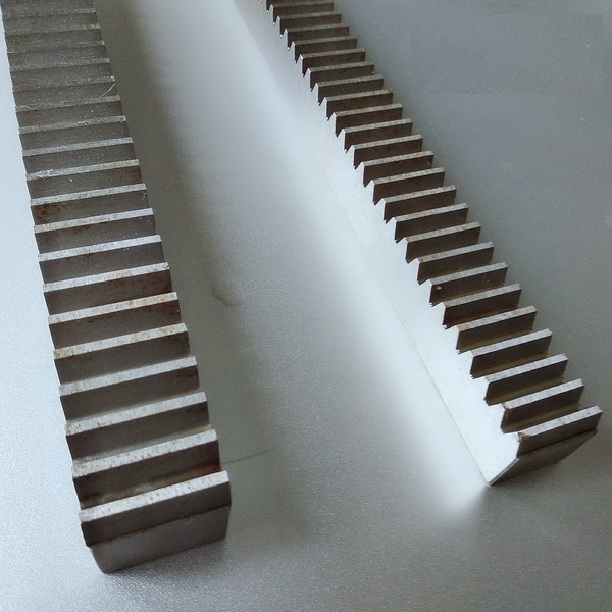

Detailed Photos

Product Description

| Material | Alloy Steel, Copper alloy(brass,silicon bronze,phosphor bronze,aluminum bronze,beryllium copper),Stainless Steel,Aluminum,Titanium, Magnesium, Superalloys,Molybdenum, Invar,,Zinc,Tungsten steel,incoloy,Nickel 200,Hastelloy, Inconel,Monel,ABS, PEEK,PTFE,PVC,Acetal. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Producing Equipment | CNC machine,automatic lathe machine,CNC milling machine,lasering,tag grinding machine etc. |

| Drawing Format | Pro/E, Auto CAD, CZPT Works, UG, CAD/CAM, PDF |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

Quality Control

Packaging & Shipping

Customer Reviews

FAQ

Q1:What kind of information do you need for quotation?

A: You can provide 2D/3D drawing or send your sample to our factory, then we can make according to your sample.

Q2: Can we CZPT NDA?

A: Sure. We can CZPT the NDA before got your drawings.

Q3: Do you provide sample?

A: Yes, we can provide you sample before mass order.

Q4: How can you ensure the quality?

A: We have profesional QC,IQC, OQC to guarantee the quality.

Q5: Delivery time?

A: For samples genearlly need 25 days. Mass production: around 30~45 days after receipt of deposit (Accurate delivery time

depends on specific items and quantities)

Q6: How about the transportation?

A: You can choose any mode of transportation you want, sea delivery, air delivery or door to door express.

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

What is a driveshaft and how much does it cost to replace one?

Your vehicle is made up of many moving parts. Knowing each part is important because a damaged driveshaft can seriously damage other parts of the car. You may not know how important your driveshaft is, but it’s important to know if you want to fix your car. In this article, we’ll discuss what a driveshaft is, what its symptoms are, and how much it costs to replace a driveshaft.

Repair damaged driveshafts

A damaged driveshaft does not allow you to turn the wheels freely. It also exposes your vehicle to higher repair costs due to damaged driveshafts. If the drive shaft breaks while the car is in motion, it may cause a crash. Also, it can significantly affect the performance of the car. If you don’t fix the problem right away, you could risk more expensive repairs. If you suspect that the drive shaft is damaged, do the following.

First, make sure the drive shaft is protected from dust, moisture, and dust. A proper driveshaft cover will prevent grease from accumulating in the driveshaft, reducing the chance of further damage. The grease will also cushion the metal-to-metal contact in the constant velocity joints. For example, hitting a soft material is better than hitting a metal wall. A damaged prop shaft can not only cause difficult cornering, but it can also cause the vehicle to vibrate, which can further damage the rest of the drivetrain.

If the driveshaft is damaged, you can choose to fix it yourself or take it to a mechanic. Typically, driveshaft repairs cost around $200 to $300. Parts and labor may vary based on your vehicle type and type of repair. These parts can cost up to $600. However, if you don’t have a mechanical background, it’s better to leave it to a professional.

If you notice that one of the two drive shafts is worn, it’s time to repair it. Worn bushings and bearings can cause the drive shaft to vibrate unnecessarily, causing it to break and cause further damage. You can also check the center bearing if there is any play in the bearing. If these symptoms occur, it is best to take your car to a mechanic as soon as possible.

Learn about U-joints

While most vehicles have at least one type of U-joint, there are other types available. CV joints (also known as hot rod joints) are used in a variety of applications. The minor axis is shorter than the major axis on which the U-joint is located. In both cases, the U-joints are lubricated at the factory. During servicing, the drive shaft slip joint should be lubricated.

There are two main styles of U-joints, including forged and press fit. They are usually held in place by C-clamps. Some of these U-joints have knurls or grooves. When selecting the correct fitting, be sure to measure the entire fitting. To make sure you get the correct size, you can use the size chart or check the manual for your specific model.

In addition to lubrication, the condition of the U-joint should be checked regularly. Lubricate them regularly to avoid premature failure. If you hear a clicking sound when shifting gears, the u-joint space may be misaligned. In this case, the bearing may need to be serviced. If there is insufficient grease in the bearings, the universal joint may need to be replaced.

U-joint is an important part of the automobile transmission shaft. Without them, your car would have no wheeled suspension. Without them, your vehicle will have a rickety front end and a wobbly rear end. Because cars can’t drive on ultra-flat surfaces, they need flexible driveshafts. The U-joint compensates for this by allowing it to move up and down with the suspension.

A proper inspection will determine if your u-joints are loose or worn. It should be easy to pull them out. Make sure not to pull them all the way out. Also, the bearing caps should not move. Any signs of roughness or wear would indicate a need for a new UJ. Also, it is important to note that worn UJs cannot be repaired.

Symptoms of Driveshaft Failure

One of the most common problems associated with a faulty driveshaft is difficulty turning the wheels. This severely limits your overall control over the vehicle. Fortunately, there are several symptoms that could indicate that your driveshaft is failing. You should take immediate steps to determine the cause of the problem. One of the most common causes of driveshaft failure is a weak or faulty reverse gear. Other common causes of driveshaft damage include driving too hard, getting stuck in reverse gear and differential lock.

Another sign of a failed driveshaft is unusual noise while driving. These noises are usually the result of wear on the bushings and bearings that support the drive shaft. They can also cause your car to screech or scratch when switching from drive to idle. Depending on the speed, the noise may be accompanied by vibration. When this happens, it’s time to send your vehicle in for a driveshaft replacement.

One of the most common symptoms of driveshaft failure is noticeable jitter when accelerating. This could be a sign of a loose U-joint or worn center bearing. You should thoroughly inspect your car to determine the cause of these sounds and corresponding symptoms. A certified mechanic can help you determine the cause of the noise. A damaged propshaft can severely limit the drivability of the vehicle.

Regular inspection of the drive shaft can prevent serious damage. Depending on the damage, you can replace the driveshaft for anywhere from $500 to $1,000. Depending on the severity of the damage and the level of repair, the cost will depend on the number of parts that need to be replaced. Do not drive with a bad driveshaft as it can cause a serious crash. There are several ways to avoid this problem entirely.

The first symptom to look for is a worn U-joint. If the U-joint comes loose or moves too much when trying to turn the steering wheel, the driveshaft is faulty. If you see visible rust on the bearing cap seals, you can take your car to a mechanic for a thorough inspection. A worn u-joint can also indicate a problem with the transmission.

The cost of replacing the drive shaft

Depending on your state and service center, a driveshaft repair can cost as little as $300 or as high as $2,000, depending on the specifics of your car. Labor costs are usually around $70. Prices for the parts themselves range from $400 to $600. Labor costs also vary by model and vehicle make. Ultimately, the decision to repair or replace the driveshaft will depend on whether you need a quick car repair or a full car repair.

Some cars have two separate driveshafts. One goes to the front and the other goes to the back. If your car has four wheel drive, you will have two. If you’re replacing the axles of an all-wheel-drive car, you’ll need a special part for each axle. Choosing the wrong one can result in more expensive repairs. Before you start shopping, you should know exactly how much it will cost.

Depending on the type of vehicle you own, a driveshaft replacement will cost between PS250 and PS500. Luxury cars can cost as much as PS400. However, for safety and the overall performance of the car, replacing the driveshaft may be a necessary repair. The cost of replacing a driveshaft depends on how long your car has been on the road and how much wear and tear it has experienced. There are some symptoms that indicate a faulty drive shaft and you should take immediate action.

Repairs can be expensive, so it’s best to hire a mechanic with experience in the field. You’ll be spending hundreds of dollars a month, but you’ll have peace of mind knowing the job will be done right. Remember that you may want to ask a friend or family member to help you. Depending on the make and model of your car, replacing the driveshaft is more expensive than replacing the parts and doing it yourself.

If you suspect that your drive shaft is damaged, be sure to fix it as soon as possible. It is not advisable to drive a car with abnormal vibration and sound for a long time. Fortunately, there are some quick ways to fix the problem and avoid costly repairs later. If you’ve noticed the symptoms above, it’s worth getting the job done. There are many signs that your driveshaft may need service, including lack of power or difficulty moving the vehicle.

editor by CX 2023-06-01

China Best Sales Forging Gear Pinion Shaft for Transmission System of Grinding Machine Compressor drive shaft axle

Product Description

Product Description

| Name of a part | Quantity | part number | |||

| filter | |||||

| ˙ inlet air filter screen, front and rear sections | (A) | (A) | |||

| The ˙ bypass valve air filter element | (B) | AAP0540016-00074, P0540016-00074 | |||

| ˙ oil tank vacuum extraction filter element | 1 | AAP1404987-00014, P1404987-00014 | |||

| ˙ oil system filter element (single filter type) | 1 | AAP1404040-5717, P1404040-5717 | |||

| ˙ oil system filter element (dual filter type) | 2 | AAP1401435-01233, P1401435-01233 | |||

| lube | |||||

| ˙TurboBlend lubricant (5 G / 20 L barrel) | (C) | AAP145710-5714, P145710-5714 | |||

| ˙TurboBlend lubricant (55 gallon / 210 L barrel) | (C) | AAP145710-5715, P145710-5715 | |||

| ˙ Oil Sampling Package | 1 | AAP1797385-00000, P1797385-00000 | |||

| ˙ Oil pump motor and main motor ball bearing lubricating grease | 1 | AAP145710-5719, P145710-5719 | |||

| ˙ main motor coupling grease | 1 | AAP145710-00264, P145710-00264 | |||

| ˙ intake guide vane drive screw grease | 1 | AAP145710-5718, P145710-5718 | |||

| ˙ bypass valve lubricating grease (D) | 1 | AAP145710-05710, P145710-05710 | |||

| part | |||||

| Heat Exchangers (Figure 7-9 and 7-10) | |||||

| ˙K seal | 3 | AAP1408800-04941, P1408800-04941 | |||

| ˙Y seal | 6 | AAP1408800-04926, P1408800-04926 | |||

| ˙ Front end plate gasket | 3 | AAP1793932-57100, P1793932-57100 | |||

| ˙ Heat Exchanger Front End Gasket | 3 | AAP1793931-57100, P1793931-57100 | |||

| ˙ rear end plate gasket (straight tube type heat exchanger) | 3 | AAP1793932-57101, P1793932-57101 | |||

| ˙ oil cooler gasket assembly (not shown in the figure) | 1 | AAP1405680-00002, P1405680-00002 | |||

| Bypass valve (Figure 7-17) | |||||

| ˙ maintenance kit (E) | 1 | AAMB45719-00098, MB45719-00098 | |||

| ˙ seal assembly (E) | 1 | AAMB45719-5712, MB45719-5712 | |||

| Outlet air check valve (Figure 7-20) | |||||

| ˙ check valve, 3 ” diameter | 1 | AAP0540571-00185, P0540571-00185 | |||

| ˙ check valve, 4 ” diameter | 1 | AAP0540571-00183, P0540571-00183 | |||

| ˙ check valve, 5 ” diameter | 1 | AAP0540571-00186, P0540571-00186 | |||

| Main motor coupling device (Figure 7-8) | |||||

| ˙ O ring | 2 | AAP1406064-20018, P1406064-20018 | |||

| ˙ pad | 2 | AAP1406064-5717, P1406064-5717 | |||

| Condensate water discharge line (Figure 7-11) | |||||

| ˙ solenoid valve, 110V / 120V | 3 | AAP1401581-01302, P1401581-01302 | |||

| ˙ solenoid valve, 220V / 240V | 3 | AAP1401581-01341, P1401581-01341 | |||

| ˙ check valve | 3 | AAP1401581-01303, P1401581-01303 | |||

| ˙ shutdown valve | 3 | AAP1401581-571, P1401581-571 | |||

| Electronic Instruments (Fig. 7-1) | |||||

| ˙ vibrational probe | (F) | AAP1407030-57106, P1407030-57106 | |||

| ˙ RTD (Temperature Transmitter) | (F) | AAP3403629-01585, P3403629-01585 | |||

| ˙ pressure transmitter-outlet pressure | (F) | AAP0540089-05710, P0540089-05710 | |||

| ˙ pressure transmitter-System pressure (not shown in the figure) | (F) | AAP0540089-05716, P0540089-05716 | |||

| ˙ main motor current transmitter | 1 | ||||

Packaging & Shipping

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.why should you buy from us not from other suppliers?

Responsibility, high quality, on time delivery

3. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,AUD,CNY;

Accepted Payment Type: T/T,PayPal,Western Union;

Language Spoken:English,Chinese

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

Drive shaft type

The driveshaft transfers torque from the engine to the wheels and is responsible for the smooth running of the vehicle. Its design had to compensate for differences in length and angle. It must also ensure perfect synchronization between its joints. The drive shaft should be made of high-grade materials to achieve the best balance of stiffness and elasticity. There are three main types of drive shafts. These include: end yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic materials as the main structural component. The yoke includes a uniform, substantially uniform wall thickness, a first end and an axially extending second end. The first diameter of the drive shaft is greater than the second diameter, and the yoke further includes a pair of opposing lugs extending from the second end. These lugs have holes at the ends for attaching the axle to the vehicle.

By retrofitting the driveshaft tube end into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer capability of the tube yoke. The yoke is usually made of aluminum alloy or metal material. It is also used to connect the drive shaft to the yoke. Various designs are possible.

The QU40866 tube yoke is used with an external snap ring type universal joint. It has a cup diameter of 1-3/16″ and an overall width of 4½”. U-bolt kits are another option. It has threaded legs and locks to help secure the yoke to the drive shaft. Some performance cars and off-road vehicles use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are often the preferred accessory.

The end yoke is the mechanical part that connects the drive shaft to the stub shaft. These yokes are usually designed for specific drivetrain components and can be customized to your needs. Pat’s drivetrain offers OEM replacement and custom flanged yokes.

If your tractor uses PTO components, the cross and bearing kit is the perfect tool to make the connection. Additionally, cross and bearing kits help you match the correct yoke to the shaft. When choosing a yoke, be sure to measure the outside diameter of the U-joint cap and the inside diameter of the yoke ears. After taking the measurements, consult the cross and bearing identification drawings to make sure they match.

While tube yokes are usually easy to replace, the best results come from a qualified machine shop. Dedicated driveshaft specialists can assemble and balance finished driveshafts. If you are unsure of a particular aspect, please refer to the TM3000 Driveshaft and Cardan Joint Service Manual for more information. You can also consult an excerpt from the TSB3510 manual for information on angle, vibration and runout.

The sliding fork is another important part of the drive shaft. It can bend over rough terrain, allowing the U-joint to keep spinning in tougher conditions. If the slip yoke fails, you will not be able to drive and will clang. You need to replace it as soon as possible to avoid any dangerous driving conditions. So if you notice any dings, be sure to check the yoke.

If you detect any vibrations, the drivetrain may need adjustment. It’s a simple process. First, rotate the driveshaft until you find the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no noticeable vibration, you can wait for a while to resolve the problem. Keep in mind that it may be convenient to postpone repairs temporarily, but it may cause bigger problems later.

end yoke

If your driveshaft requires a new end yoke, CZPT has several drivetrain options. Our automotive end yoke inventory includes keyed and non-keyed options. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are often used to join two heads back to back. These are convenient options to help keep drivetrain components in place when driving over rough terrain, and are generally compatible with a variety of models. U-bolts require a specially machined yoke to accept them, so be sure to order the correct size.

The sliding fork helps transfer power from the transfer case to the driveshaft. They slide in and out of the transfer case, allowing the u-joint to rotate. Sliding yokes or “slips” can be purchased separately. Whether you need a new one or just a few components to upgrade your driveshaft, 4 CZPT Parts will have the parts you need to repair your vehicle.

The end yoke is a necessary part of the drive shaft. It connects the drive train and the mating flange. They are also used in auxiliary power equipment. CZPT’s drivetrains are stocked with a variety of flanged yokes for OEM applications and custom builds. You can also find flanged yokes for constant velocity joints in our extensive inventory. If you don’t want to modify your existing drivetrain, we can even make a custom yoke for you.

editor by CX 2023-05-10

Best China manufacturer & factory high in Caracas Venezuela precision Drive Planetary Crown Wheel And Pinion Toy Right Angle Bevel Gear With high quality best price

The new goods contain a series of higher-tech and large high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, substantial-velocity tooth chains, timing chains, self-lubrication chains, among which have variety substantial speed tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China.

In our sales system we offer you normal and wide-angle PTO travel shafts. Relating to the customers’ requirements there are various dimensions, lengths and basic safety aspects (clutches) accessible.

Overview

Quick Details

- Relevant Industries:

-

Manufacturing Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

.4-20

- Service:

-

Reply in 12 hours at any time

- Standard material:

-

20CrMnTi

-

In buy to find a appropriate gearbox for your software from the basic phase, our on-line SIZING ASSISTANT style instrument is best: dependent on your application info or the preferred motor, a ideal gearbox can be picked from our portfolio and geometry adjustment done in a few seconds. Upon demand, we can also send out you a ask for for quotation straight on-line.

- Material2:

-

Steel, Stainless metal, POM and many others.

- Warmth treatment method:

-

Tooth hardened HRC55-sixty three

Source Capacity

- Source Capability:

- 5000 Piece/Pieces for each Month

Packaging & Shipping

- Packaging Details

- Antirust oil + Paper bag + Wood case

- Port

- Ningbo, Shanghai or as request

-

Direct Time

: -

Quantity(Baggage) 1 – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(days) thirty 40 60 To be negotiated

Online Customization

high precision Push Planetary Crown Wheel And Pinion Toy Proper Angle Bevel Equipment

Spiral bevel gears

Our spiral bevel gears are welcomed by several buyers for its steady substantial quality and competitive cost.

The producing character of JH spiral bevel gears:

1. Gear size: the greatest diameter is 1800mm

two. Material: Most typical metal is higher power steel 20CrMnTi. Others can be steel C45, stainless steel, substantial strength metal, copper, aluminium, plastic, POM and so forth

3. Spiral bevel Gear module: .3-twenty (pitch from .942-62.80mm, DP 1.27-85)

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so on.

5. Quality: steady and high, grade 7 for without tooth grinding, grade 6 soon after enamel grinding, quality 5 for exact grinding.

Costs for over high quality are very aggressive for us.

6. Heat remedy: teeth can be hardened to HRC fifty five-63.

The good quality character of JH spiral bevel gears:

1. Stable transmission and lower sounds

2. Effectively avoid typical tolerance dependent on high precision

3. The enamel can be floor to grade 6 and quality 5 top quality

four. The bore will be polished to smooth and large precision

5. The price is competitive even the good quality is higher.

| Facilities |

Machining centre, Gleason machines, CNC equipment hobbing machine, CNC equipment shaper, CNC equipment grinding device, CNC turning machine, CNC milling machine, Y58200 CNC big equipment rack shaper, Y58125A equipment rack shaper, England gear rack shaper, and Russia equipment rack shaper, |

| Equipment varieties |

Helical gears (a lot more and more widely used for its secure transimission) Spur gears Hub gears Bevel gears Bevel spiral gears Equipment ring and so forth. |

| Substance |

Metal: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and so forth. Aluminium alloy: 6061, 5083, 7050, etc. A lot more: PA6, PA66, POM, Abdominal muscles and many others. |

| Area | Polishing Plating Galvanized Blacken chromium plating, nickel plating painting and so on. |

Complete expertise on Spiral bevel gears

Our Providers

one. Shipping time: 15-25 days for small purchase

30-45 times for large get. (By no means delayed till now)

Can be mentioned for more urgent buy.

2. Response time: usually in 1 hour and in twelve hours even in our vacations.

three. Procedure feedback: Photos or vedios will be sent for 2-3 instances to inform you the creating situation.

four. Examination report: The take a look at report can be supplied as request.

5. Payment conditions: T/T, L/C, D/P, D/A, O/A, M/T, D/D and many others.

6. Trade phrases: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Info

FAQ

Q: Company?

A: Indeed. Because 2004 only emphasis on generating high high quality gears and racks.

Q: Reaction time?

A: Reply quite before long, and reply in 12 hrs at any time.

Our technicians are often jointly with salesmen, so your any questions can be replied really shortly.

Q: Price?

A: Drawings are a lot more appriated for quotation. Or, make sure you tell us your request, we will make drawings for your examine.

Q: Delivery time?

A: 15-25 days for modest order (<200 pcs), 30-45 days for large order.

Orders in no way be delayed, the items will be despatched on time as arrangement.

Q: Top quality?

A: Middle and higher high quality is more aggressive.

Q: Payment conditions?

A: T/T for significantly less than US$twenty,000 order, and L/C, D/P, D/A, O/A, M/T, D/D and so on. for massive orders.

Q: Trade conditions?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Our company has strong financial strength, builds up a technician staff contingent with large quality, possesses the generation assembly line of technicalization in China and excellent system checking on solution top quality and runs marketing and advertising networks throughout the place.

Scorching related merchandise

Contact us

Best China manufacturer & factory M1 in Merca Somalia small bevel pinion gear With high quality best price

Our AdvantagesProducts Massive quantity in Inventory, No MOQ necessary We comply with all the global standards, these kinds of as ISO9001 and TS16949 specifications.

Overview

Rapid Details

- Applicable Industries:

-

Producing Plant

- Area of Origin:Zhejiang, China

- LocEPG is inclined to cooperate sincerely and produce commonly with friends!al Provider Spot:

-

None

- Certification:

-

ISO9002 Certification

- other:

-

spiral bevel equipment

- spiral gear:

-

equipment wheel

Offer Capacity

- Source Capacity:

- one million Piece/Items for each Month

Packaging & Shipping

- Packaging Information

- Metal Pallet or Poly-wood Scenario

- Port

- Shanghai or Ningbo

-

Guide Time

: -

Amount(Packing containers) 1 – 100 Owing to these characteristics, common worm equipment purposes contain presses, modest engines, lifts and elevators, rolling mills, conveying engineering, mining business machines, on rudders, and worm travel saws.

>100 Est. Time(times) thirty To be negotiated

On-line Customization

Solution Description

M1 Small Bevel Pinion Gear

| Functions: |

1. Materials: 20CrMnTi

2. Processing: Forged, machined, warmth treatment method

three. Quality: OEM.

4. Can layout and manufacture as for each your drawing or sample

We can make regular equipment and special gear as for every drawing or sample

The gear content can be carbon steel, stainless metal, aluminum, copper, brass and so on.

We can do warmth treatment andsurface treatment method such as situation harden, zinc plating , nick plating , chrome plating, powder coating, blacken and so on.

Our procedure includes tooling fabrication, stamping, deep drawing, punching, spinning, laser slicing, bending, seamless welding, machining and assembly.

Application: Electronic/Appliance/Automobile/Industrial products steel stamping hardware components

| Quantity(Pieces) | 1 | >1 |

| Est. Time(days) | thirty | To be negotiated |

Main Merchandise

Organization Details

Hangzhou Ever-Electrical power Industry Co., Ltd. is a specialized provider of a total assortment of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined areas and so on.

Owing to our sincerity in giving best support to our consumers, knowing of your wants and overriding sense of responsibility towards filling buying demands, we have received the have faith in of buyers globally. Getting gathered precious knowledge in cooperating with international customers, our merchandise are marketing properly in the American, European, South American and Asian markets.Our goods are manufactured by modern day computerized equipment and equipment. In the meantime, our goods are manufactured according to high quality specifications, and complying with the global sophisticated regular requirements.

With many years’ knowledge in this line, we will be trusted by our advantages in competitive price tag, 1-time shipping and delivery, prompt response, on-hand engineering assist and good after-revenue solutions.

In addition, all our manufacturing methods are in compliance with ISO9001 standards. We also can style and make non-standard products to fulfill customers’ special requirements. High quality and credit history are the bases that make a company alive. We will provide ideal providers and large high quality merchandise with all sincerity. If you need any details or samples, make sure you contact us and you will have our quickly reply.

Exhibition

Make contact with Us

Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Designs a few distinct sorts of PTO in operation: a non shear, shear pin and slip clutch — the last currently being the most costly. Implement stop of non shear (r) and shear type (l) Non shear: this is a reliable yoke to yoke set up and employed with the expectation that specified tools will not experience any sudden stops. I determine that the ending mower does not need to have a shear set up as the blades will slip to a diploma getting belt pushed and my other mower, the flail mower, is incredibly forgiving in its layout.

factory High Quality Price Ratio manufacturer for High quality precision steel gleason spiral bevel gear standard spur pinion custom driving wheel

In 2000, EPG took the lead in getting ISO14001 environment management certificate and thereafter handed the inspection of thoroughly clean generation and recycling financial system, successful the title of “Zhejiang Green Enterprise”.

Overview

Quick Details

- Relevant Industries:

-

Producing Plant

- Product Search phrases:

-

precision steel gleason spiral bevel equipment

Offer Ability

- Supply Ability:

- 5000 Piece/Pieces for each Month

Packaging & Shipping and delivery

- Packaging Particulars

- Neutral paper packaging, picket bins for outer box or in accordance to customer’s desire.

- Port

- Shanghai Port / Ningbo Port

On-line Customization

We At any time-Power Team with 4 branches over 1200 staff is a single of the most significant transmission elements and machining products companies in China

Product Description

Solution Description:

We specialized in producing car gears , motorbike gears, gearbox, specific vehicle (electricity takeoff, snowmobiles, engineering cars) gears, generator accessories, stainless steel ice crusher etc.

|

Materials |

1020,1045,20CrMnTi, and so forth. |

|

Machining Process |

Equipment Hobbing , Gear Shaping, Gear Shaving, Equipment Grinding |

|

Modules |

one., one.25, 1.five, 1.seventy five, two., 2.twenty five, 2.5….eight. etc. |

|

Warmth Treatment |

Carburizing & Quenching, Carbonitriding |

|

Common |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |