The new goods contain a series of higher-tech and large high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, substantial-velocity tooth chains, timing chains, self-lubrication chains, among which have variety substantial speed tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China.

In our sales system we offer you normal and wide-angle PTO travel shafts. Relating to the customers’ requirements there are various dimensions, lengths and basic safety aspects (clutches) accessible.

Overview

Quick Details

- Relevant Industries:

-

Manufacturing Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

.4-20

- Service:

-

Reply in 12 hours at any time

- Standard material:

-

20CrMnTi

-

In buy to find a appropriate gearbox for your software from the basic phase, our on-line SIZING ASSISTANT style instrument is best: dependent on your application info or the preferred motor, a ideal gearbox can be picked from our portfolio and geometry adjustment done in a few seconds. Upon demand, we can also send out you a ask for for quotation straight on-line.

- Material2:

-

Steel, Stainless metal, POM and many others.

- Warmth treatment method:

-

Tooth hardened HRC55-sixty three

Source Capacity

- Source Capability:

- 5000 Piece/Pieces for each Month

Packaging & Shipping

- Packaging Details

- Antirust oil + Paper bag + Wood case

- Port

- Ningbo, Shanghai or as request

-

Direct Time

: -

Quantity(Baggage) 1 – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(days) thirty 40 60 To be negotiated

Online Customization

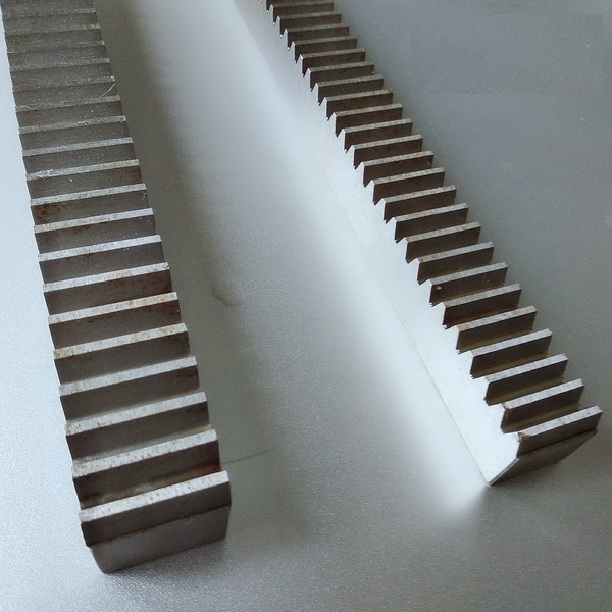

high precision Push Planetary Crown Wheel And Pinion Toy Proper Angle Bevel Equipment

Spiral bevel gears

Our spiral bevel gears are welcomed by several buyers for its steady substantial quality and competitive cost.

The producing character of JH spiral bevel gears:

1. Gear size: the greatest diameter is 1800mm

two. Material: Most typical metal is higher power steel 20CrMnTi. Others can be steel C45, stainless steel, substantial strength metal, copper, aluminium, plastic, POM and so forth

3. Spiral bevel Gear module: .3-twenty (pitch from .942-62.80mm, DP 1.27-85)

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so on.

5. Quality: steady and high, grade 7 for without tooth grinding, grade 6 soon after enamel grinding, quality 5 for exact grinding.

Costs for over high quality are very aggressive for us.

6. Heat remedy: teeth can be hardened to HRC fifty five-63.

The good quality character of JH spiral bevel gears:

1. Stable transmission and lower sounds

2. Effectively avoid typical tolerance dependent on high precision

3. The enamel can be floor to grade 6 and quality 5 top quality

four. The bore will be polished to smooth and large precision

5. The price is competitive even the good quality is higher.

| Facilities |

Machining centre, Gleason machines, CNC equipment hobbing machine, CNC equipment shaper, CNC equipment grinding device, CNC turning machine, CNC milling machine, Y58200 CNC big equipment rack shaper, Y58125A equipment rack shaper, England gear rack shaper, and Russia equipment rack shaper, |

| Equipment varieties |

Helical gears (a lot more and more widely used for its secure transimission) Spur gears Hub gears Bevel gears Bevel spiral gears Equipment ring and so forth. |

| Substance |

Metal: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and so forth. Aluminium alloy: 6061, 5083, 7050, etc. A lot more: PA6, PA66, POM, Abdominal muscles and many others. |

| Area | Polishing Plating Galvanized Blacken chromium plating, nickel plating painting and so on. |

Complete expertise on Spiral bevel gears

Our Providers

one. Shipping time: 15-25 days for small purchase

30-45 times for large get. (By no means delayed till now)

Can be mentioned for more urgent buy.

2. Response time: usually in 1 hour and in twelve hours even in our vacations.

three. Procedure feedback: Photos or vedios will be sent for 2-3 instances to inform you the creating situation.

four. Examination report: The take a look at report can be supplied as request.

5. Payment conditions: T/T, L/C, D/P, D/A, O/A, M/T, D/D and many others.

6. Trade phrases: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Info

FAQ

Q: Company?

A: Indeed. Because 2004 only emphasis on generating high high quality gears and racks.

Q: Reaction time?

A: Reply quite before long, and reply in 12 hrs at any time.

Our technicians are often jointly with salesmen, so your any questions can be replied really shortly.

Q: Price?

A: Drawings are a lot more appriated for quotation. Or, make sure you tell us your request, we will make drawings for your examine.

Q: Delivery time?

A: 15-25 days for modest order (<200 pcs), 30-45 days for large order.

Orders in no way be delayed, the items will be despatched on time as arrangement.

Q: Top quality?

A: Middle and higher high quality is more aggressive.

Q: Payment conditions?

A: T/T for significantly less than US$twenty,000 order, and L/C, D/P, D/A, O/A, M/T, D/D and so on. for massive orders.

Q: Trade conditions?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Our company has strong financial strength, builds up a technician staff contingent with large quality, possesses the generation assembly line of technicalization in China and excellent system checking on solution top quality and runs marketing and advertising networks throughout the place.

Scorching related merchandise

Contact us